Electronic and Electrical Products Quality Inspection and Quality Assurance

GIS Inspection provides quality control and quality assurance services including product inspections and factory audit for a great variety of electrical and electronics products. GIS's electrical & electronics department, a team of technical managers, inspection engineers, and audit specialists, enforces strict adherence to buyer-specified quality plans and industry regulations.

By prioritizing quality inspection, both electronic and electrical manufacturers and buyers can ensure safety and regulatory compliance and maintain quality, customer satisfaction, and overall business success.

To ensure your electronics products are reliable, safe and compliant, book an inspection today!

The electronic and electrical Products GIS can Inspect

GIS Inspection, as a global quality inspection and testing service provider, offers comprehensive inspection solutions for a wide range of electronic and electrical products. Below are the key types of electronic and electrical products that GIS can inspect, ensuring compliance with industry standards, safety regulations, and quality specifications:

Home Appliances:

Fridge, Air Condition, Washing Machine, Coffee Machine, Toaster, Microwave Oven, Clothes Dryer, etc.

Lights and Lighting:

Save Energy Lamp, Christmas Light, Sensor Light, Torches, Table Lamp, Lantern, LED Light, Bicycle Light, Post Lamp, etc.

Electrical Accessories:

Charger, Battery, Transformer, Accessories Parts, etc.

Computer Device:

MP3 Player, Keyboard, Card Reader, USB Hub, Mouse, Printer, Digital Camera, etc.

Power Tools:

Power polishers & buffers, grinders, power saws, screw guns & power screwdrivers, power impact wrenches, sanders, power lathes, power rotary tools, power nailers & staplers, shop wet dry vacuums.

Electronic Equipment:

Door Bell or Chime, Security System, Alarm Device, Remote Control, Multifunction Detector, GPS Receiver/ Navigator, etc.:

Regulations and Standards for Electronic and Electrical Quality Control

Electrical safety regulations and standards are designed to ensure the safe installation, operation, and maintenance of electrical systems and equipment. These standards cover a wide range of requirements, including the design and installation of electrical installations, the safety use of electric products, and procedures for safely working on or near electrical components.

1. International Standards for Electronic and Electrical product safety

The IEC (International Electrotechnical Commission) develops international standards for electrical and electronic products, focusing on safety, performance, and environmental impact.

- IEC 60950: Safety of Information Technology Equipment (replaced by IEC 62368).

- IEC 61000: Electromagnetic Compatibility (EMC) standards for minimizing interference.

- IEC 60065: Safety requirements for audio, video, and similar electronic apparatus.

- IEC 60335: Safety of household and similar electrical appliances.

2. Electronic and Electrical product Regulations and Standards in the EU

RoHS Directive

The RoHS Directive restricts the use of hazardous substances (e.g heavy metals) in electrical and electronic equipment. No matter what kind of electronic products you are importing, you must ensure that your products do not contain an excessive amount of restricted substances.

Low Voltage Directive (LVD)

The Low Voltage Directive (LVD) aims at protecting European citizens from the electrical hazards of electrical equipment within certain voltage limits.

EMC Directive

The Electromagnetic Compatibility (EMC) Directive limits the electromagnetic emissions from electrical and electronic equipment to make sure that when said equipment is used correctly, it does not disturb the functionality of radio and telecommunication, as well as other equipment. Similarly, it governs the immunity of said equipment from interference by radio emissions when used as intended.

Electronic Toys: Toy Safety Directive

The Toy Safety Directive aims at ensuring that toys are safe for children to play with. One of the goals of the directive is to make sure that toys meet strict safety requirements, including with regards to electrical safety.

- EN 62115: Electric toys - Safety

- EN 71: Safety of toys

CE Marking

Products covered by one or more CE directives must carry the CE mark. This essentially includes all electronic products. The CE mark indicates conformity with the requirements of applicable directives when manufacturing, importing or selling in the EU market. The CE mark must be permanently affixed to the product and its packaging.

Read more: Which Countries Require CE Marked Products?

General Product Safety Directive (GPSD)

The General Product Safety Directive (GPSD) applies to consumer products placed in the EU market. Its goal is to ensure that products are safe to protect consumers’ health and safety.

REACH

REACH restricts chemicals and heavy metals in consumer products sold in the EU, including electronics.

3. CCC Regulations and Standards in China

The CCC (China Compulsory Certification) mark is required for most electrical products sold in China, ensuring compliance with Chinese safety and quality standards.

- GB 4706.1: General requirements for household and similar electrical appliances (China’s equivalent of IEC 60335).

- GB/T 17626: Electromagnetic compatibility standards in China.

- GB 8898: Safety requirements for audio, video, and similar electronic equipment.

Electric products quality control inspection is virtual to ensure that products meet the necessary standards, providing customers with safety.

Adhering to these standards ensures that electric products are safe, reliable, and compliant with industry best practices. Manufacturers, brands, and importers who prioritize E quality control based on these applicable standards can offer products that meet customer expectations, enhance brand reputation, and contribute to a positive and trustworthy market presence.

Types of Third-party Electronic and Electrical Products Quality Control Service

Electronic and Electrical product buyers demand that their suppliers meet high product quality specifications. As a global third-party inspection company, GIS Inspection offers quality solutions throughout the entire production cycle.

This allows our customers to identify defects, ensure product quality, and avoid product recall. Our electrical and electronics products quality control services include:

Factory Audit

A Factory Audit ensures that the supplier or vendor can design and produce according to normative requirements. It also ensures that a new or existing manufacturer can deliver quality products, undertake continuous improvements and operate efficiently.

GIS’s auditor qualifies or disqualifies a potential supplier based on manpower, production capability, production and related system, quality control, follow up and suggestions before you start working with them.

Pre-Production Inspection(PPI)

A on-site check on the electrical and electronics products, workmanship, safety, labels, and quality of Electronic and Electrical products at the beginning or even before of production, against the clients’ specifications, technical drawings and golden sample.

During Production Inspection (DUPRO)

A check on the dimensions of components, quality of materials and finished products during electrical and electronics products industry manufacturing to identify issues early.

Pre-Shipment Inspection(PSI)

PSI also called Final Random Inspection (FRI) -A detailed visual and final inspection in electrical and electronics products industry on randomly selected finished clothing products. It takes place when the merchandise is completed, packed and ready for shipment. The quantity, workmanship, function, color, size specifications safety test, and packing details are verified to ensure that the contract specifications are met.

Loading Supervision (LS)

A Container Loading Supervision is an on-site inspection service designed to ensure your products are shipped exactly as ordered, in the right quantities and condition. GIS loading supervision services check your products before shipment to ensure the intended goods and quantity loaded into the container are in accordance with your purchase order.

Electronic and Electrical Products Quality Inspection Checklists

A comprehensive electrical and electronics products PSI checklist is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

1. Quantity Check

GIS inspectors count products and shipping cartons to verify that the correct quantity of an order has been finished which including PO quantity, shipment quantity, packed quantity, unpacked quantity, and unfinished quantity.

2. Workmanship Inspection

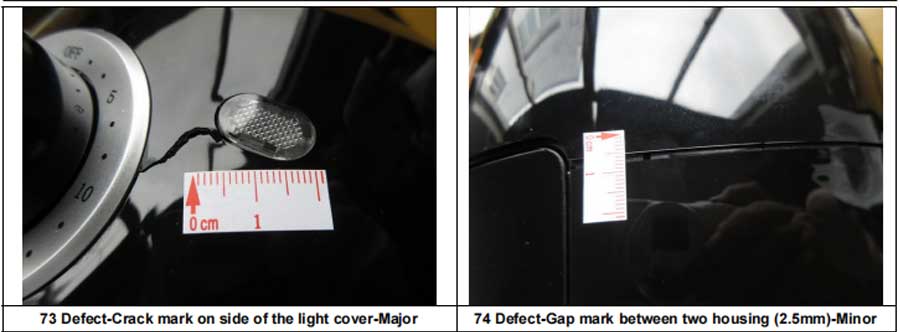

The inspector will select a sample size according to the AQL standard, and conduct a visual check for any damages and flaws in workmanship and classify them as major, minor, or critical defects.

3. Product description, style and color check

GIS Inspection will verify that the products conform to the specifications against PO, photos, and sample.

4. On-site Test

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards. The essential tests performed by our inspectors during an onsite inspection of garments and apparel:

- Hi voltage check

- Earth resistance check

- Basic function check

- Transportation Drop Test

- Power on check

- Internal check for workmanship

- Temperature measurement

- Stability check at 15 degree

- Rub and tape test on Logo

- Product measurement

- Timer function check

- CDF check

- Power consumption check

- Barcode readability check

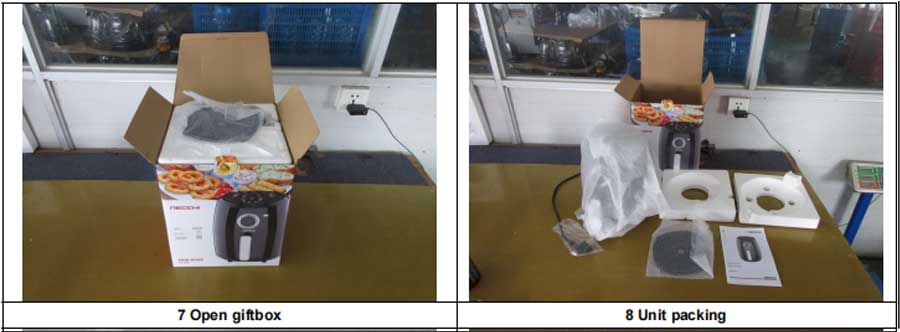

5. Packaging Check

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

6.Shipping mark check

This checklist can be customized depending on the specific type of Electronic and Electrical product (e.g., home appliance, automotive device, consumer electronics, etc.). It covers key quality aspects that help ensure products are safe, functional, and compliant with industry standards before reaching the market.

Check a Sample Report for Electronic and Electrical Products Inspection

GIS Electronic and Electrical Products Quality Control in China, India, Vietnam, and Malaysia

Electrical and electronics products can pose significant safety risks if they are not designed and manufactured to the highest safety standards. Poor quality products or products that do not comply with safety regulations can cause fires, electrical shocks, and other personal and household hazards.

While most safety parameters are measured and verified by on-site quality inspection and laboratory testing provided by GIS Inspection Assurance network of companies can help to provide added views of safety and quality performance before goods are shipped.

Whether you are a seller, importer, exporter or manufacturer in the industry, running field quality check gives extra assurance in the quality and safety aspect.

At GIS Inspection, we’ve helped businesses in the electronics industry for 20 years with our quality control services for the electronics industry. We have set up a network of China, Vietnam, Malaysia, and India to help buyers ensure the Electronic and Electrical industry supply chain. Contact us today if you need assistance with quality control services for your electronics business.

GET A QUOTE