Soft Goods Quality Inspection and Quality Assurance

GIS Inspection provides third-party quality control and quality assurance services enable you to ensure quality and safety in soft goods with a variety of products like apparel, textile, fabric, footwear, bags to support your regulatory compliance in different consumer markets.

GIS's soft goods department, a team of technical managers, inspection engineers, and audit specialists, enforces strict adherence to buyer-specified quality plans and industry regulations.

By prioritizing quality inspection, both soft goods manufacturers and buyers can ensure safety and regulatory compliance and maintain quality, customer satisfaction, and overall business success.

To ensure your soft goods products are reliable, safe and compliant, book an inspection today!

The Soft Goods Products GIS can Inspect

It is a vital step in ensuring soft goods excellence, compliance, and consumer safety. By investing in comprehensive inspections, brands can mitigate risks, enhance market competitiveness, and build lasting trust with their customers.

GIS Inspection, as a leading third-party quality control provider, specialize in inspecting a broad range of soft goods. Below is an overview of soft goods categories that GIS Inspection can inspect:

Safety Shoes, Hiking Shoes, Sport Shoes, etc.

Sheet, Pillow, Quilt, Curtain, etc.

Knitted Fabric, Woven Fabric, Nonwoven Fabric, etc.

Portfolio, Single-shoulder Bag, Backpack, Satchel, Field Bag, etc.

- Other soft goods

Types of Third-party Soft Goods Products Quality Control Service

Soft goods buyers demand that their suppliers meet high product quality specifications. As a global third-party inspection agency, GIS Inspection offers quality solutions throughout the entire soft goods production cycle.

This allows our customers to identify defects, ensure product quality, and avoid product recall. Our soft goods quality control services include:

Factory Audit

A Factory Audit ensures that the supplier or vendor can design and produce according to normative requirements. It also ensures that a new or existing manufacturer can deliver quality products, undertake continuous improvements and operate efficiently.

GIS’s auditor qualifies or disqualifies a potential supplier based on manpower, production capability, production and related system, quality control, follow up and suggestions before you start working with them.

Pre-Production Inspection(PPI)

A on-site check on the soft goods, workmanship, safety, labels, and quality of soft goods at the beginning or even before of production, against the clients’ specifications, technical drawings and golden sample.

During Production Inspection (DUPRO)

A check on the dimensions of components, quality of materials and finished products during soft goods industry manufacturing to identify issues early.

Pre-Shipment Inspection(PSI)

PSI also called Final Random Inspection (FRI) -A detailed visual and final inspection in soft goods industry on randomly selected finished clothing products. It takes place when the merchandise is completed, packed and ready for shipment. The quantity, workmanship, function, color, size specifications safety test, and packing details are verified to ensure that the contract specifications are met.

Loading Supervision (LS)

A Container Loading Supervision is an on-site inspection service designed to ensure your soft products are shipped exactly as ordered, in the right quantities and condition.

GIS loading supervision services check your products before shipment to ensure the intended goods and quantity loaded into the container are in accordance with your purchase order.

What are the Major Inspection Criteria for Softline?

The major inspection criteria for softlines which is differ depending on the market, its purpose, and to whom the product is intended ensure the products meet quality, safety, and performance standards. The major inspection criteria for softline are:

1. Materials, colors, and styles

Via visual inspections can help to ensure your products meet your customers’ expectations and prevent defects, including materials, color, and style. The color inspection is intended to determine whether the color match the sample swatches, reference sample or color chart.

2. Accessories

For accessories, like buckles, belts, ornamentation, must match the sample and description. For example, buckles should be smooth, well plated without burrs and well positioned at the correct place.

3. Measurements

The products’ measurements will be inspected and checked to ensure they comply with the correct specifications.

4. Needle Check

Needles are used for garment sewing but they sometimes get left behind and end up hidden in clothing. Needle check is a major procedure for any broken or existing needles inside. It allows factory to remove unwanted items before goods are shipped, removing the risk of product recalls and injury.

5. Labeling and Hangtags

Most articles are provided with a label or a hangtag. Some countries have stringent laws regarding the compulsory labeling of articles.

During inspection for quality, the checking of the labels must not be neglected. For example, the indication on the hangtag must be identical with the sewn-in label in the garment and the size must be consistent.

6. Assortment

The assortment check is also important. Large retail chain stores distribute standard packed items to their numerous sales outlets, e.g. a master carton will contain 50 red, 50 black, 30 green and 20 blue ones. Some unscrupulous manufacturers, for lack of a specified color or size, may be tempted to make up the shortage by some other colors or sizes.

Soft goods inspection involves a thorough evaluation of materials, workmanship, functionality, and compliance. Addressing these key elements ensures products meet quality standards, reduce defect risks, and align with customer expectations.

Soft Goods Products Quality Inspection Checklists

A comprehensive soft goods pre-shipment checklist is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

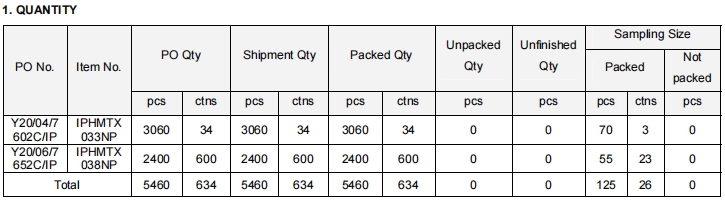

1. Quantity Check

GIS inspectors count products and shipping cartons to verify that the correct quantity of an order has been finished which including PO quantity, shipment quantity, packed quantity, unpacked quantity, and unfinished quantity.

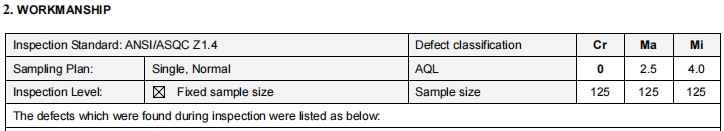

2. Workmanship Check

The inspector will select a sample size according to the AQL standard, and conduct a visual check for any damages and flaws in workmanship and classify them as major, minor, or critical defects.

3. Product description, style and color check

GIS Inspection will verify that the products conform to the specifications against PO, photos, and sample.

4. On-site Test

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards. The essential tests performed by our inspectors during an onsite inspection of soft goods:

- Drop test

- Assortment check

- Metal detection

- Color shade check

- Function check

- Reliability test for Zipper/button/snap or any other functional component

- GSM test per fabric type

- Product size / Weight measurement

- Tape test on printed label

- Fitting check

- Barcode readability check

- Tension test

- Odor check

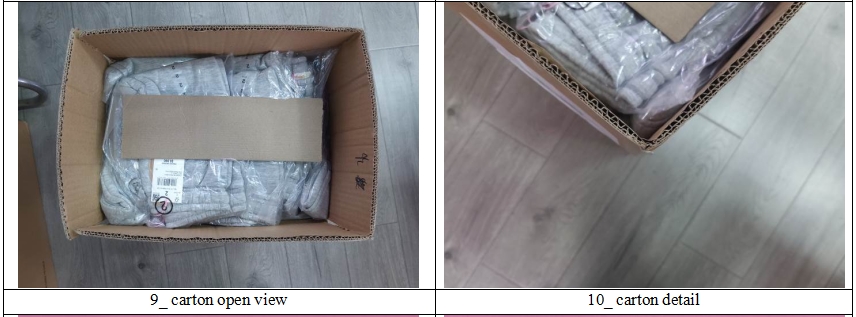

5. Packaging check

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

Check a Sample Report for Electric Products Inspection

GIS Soft Goods Products Quality Control in China, India, Vietnam, and Malaysia

GIS Inspection is a leading third-party quality inspection agency, our safety parameters can help to provide added views of safety and quality performance before goods are shipped.

Whether you are a seller, importer, exporter or manufacturer in the industry, running field quality check gives extra assurance in the quality and safety aspect.

At GIS Inspection, we’ve helped businesses in the soft goods industry for 20 years with our quality control services. We have set up a network of China, Vietnam, Malaysia, and India to help buyers ensure the soft goods industry supply chain. Contact us today if you need assistance with quality control services for your soft goods business.