During Production Inspection(DUPRO) is a vital step within the quality assurance process for the manufacturing industry, which serves as a proactive measure that helps in minimizing the risk of significant quality failures.

GIS Inspection is a leading third-party quality control agency in China, we provide during production random inspection service in Asia. During Production Inspection service assists in verifying that your factory is following your original specifications correctly, ensuring that the project remains on track to meet its deadlines.

Our During Production Inspection works for all kinds of products and is typically ideal for electric and electronic products and poorly performed factories.

What is During Production Inspection?

During Production Inspection, also referred to DUPRO, is a critical quality control process that performed when 30%-50% of goods are completed. Its purpose is to check that the factory follows the original specifications correctly and that the output is still on schedule.

DUPRO (During production inspection) can help to detect and correct any issues or defects that could affect the quality or delivery of the products. It allows you to identify any issues or defects early on and enables manufacturers to take corrective actions before large quantities of defective products are produced.

Unlike Pre-Production Inspection(PPI), which assesses raw materials and components before manufacturing begins, DUPRO checks products during the manufacturing process.

This mid-production check differs from Pre-Shipment Inspection (PSI), which takes place after production is fully completed and just before shipping. PSI emphasizes the end product's adherence to quality standards and order specifications, with no opportunity for corrective action during the production process.

The Importance of During Production Inspection

During Production Inspection plays a vital role in ensuring quality, efficiency, and compliance throughout the manufacturing process. Here are some of the key reasons:

- Early Detection of Defects: During Production Inspection is the early identification of defects in the manufacturing process. Identifying the issues in early stage allows manufacturers to take corrective actions immediately. This proactive approach prevents the defects from affecting a larger batch of products, thereby safeguarding product quality and reducing costs.

- Cost Efficiency: By detecting and addressing quality issues at a relatively early stage, businesses can establish effective workarounds to rectify any defective products promptly. This proactive approach prevents these issues from escalating and causing further delays in the production timeline.

- Production Schedule Management: By continuously assessing production progress and quality, DUPRO inspectors can identify delays or deviations from the planned timeline early, allowing management to make the necessary adjustments to keep the project on track.

- Enhanced supplier management: During Production Inspection provides valuable insights into a supplier’s production capabilities, quality control systems, and adherence to contractual obligations.

Inclusive, During Production Inspection is a quality control process that enhances product quality, reduces operational costs, ensures timely production, and improves supplier performance, making it an indispensable part of modern manufacturing practices.

When should You Conduct a During Production Inspection?

During Production Inspections (DPI) are usually scheduled at a specific point in the production process when a certain percentage of the products have been produced. This is usually done to identify and address any issues that may arise during the production process before the product is completed.

- The products have strict compliance requirements e.g. electrical and electronic products. To ensure that product quality and specifications are in line with standards and regulations during the mass production stage.

- The existing factory performs poorly constantly.

- The production quantity is large and on-time shipment is important avoiding production delays .

Get in touch with GIS Inspection to learn more.

How to Conduct a During Production Inspection?

A During Production Check is one of the best ways to ensure that your product meets your requirements. It aims to visual check on production schedule, verify production capacity and output, product quality, quantity, safety, function, labeling, marking, packaging, and other required parameters.

GIS Inspection has an extensive professional inspection checklists available that are designed for particular products. Here’s how GIS Inspection conduct a During Production Inspection:

1. Product specifications

Sample and evaluate the products for safety, performance, design, function and appearance;

2. Product quality

Check for any defects and deviation from clients’ specifications and/or given samples; Verify that the products are being manufactured according to the original specifications, such as size, colour, weight, material, and design.

3. Packing and packaging checks

Verify the unit packing, inner packing, and outer packing to ensure that they meet the required specifications; Check the export carton dimensions and weights to ensure that they meet the shipping requirements; Verify the shipping marks on cartons to ensure that they are properly labeled.

4. Production management

Check and evaluate the quality management of production line; Detailed check of the manufacturing procedures and the condition and suitability of the equipment used, ensuring everything functions as intended.

5. Production progress

Evaluate the production progress against the schedule and predict if the shipment is on schedule; Delays or accelerations in production are noted for further evaluation.

6. Improvement plan

Give practical and effective advises to improve quality in accordance of the findings.

What is the Procedure of During Production Inspection?

There are 9 important procedures that GIS During Production Inspection service performance:

1. Opening Meeting

Have an opening meeting with factory.

2. Quantity Verification

Count products to verify that the correct quantity of an order has been finished, unpacked, still in production. Review the production timeline and actual progress to ensure the project is on track.

3. Random Sampling

Randomly select a sample of products from already completed batches of the production to inspect according to the statistical sampling procedure ISO 2859-1.

4. Product and Workmanship Check

Verify that the products conform to the specifications against PO, photos, and sample; Conduct a visual check for any damages and flaws in workmanship.

5. Production Line Check

Check and evaluate the quality management of production line.

6. Function and Safety Test

Test to ensure that its functions properly and meets safety standards.

7. Packing and packaging checks

Evaluate the packing methods and packing material.

7. Close Meeting

Have a close meeting to get factory’s confirmation.

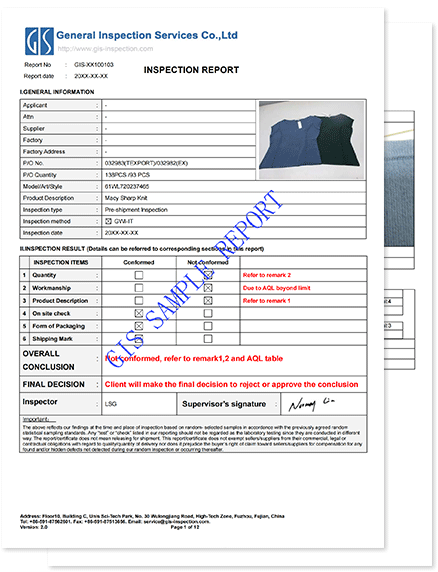

8. Inspection Report

After finish the inspection, GIS Inspection will provide you with detailed and unbiased inspection reports and certificates, verifying whether the products meet the specifications stated in your contract. The report outlines the findings of the inspection, including photos of any defects found, and gives an overall confirmed/not confirmed outcome.

DOWN A QUALITY INSPECTION SAMPLE REPORT

GIS Inspection detailed inspection reports and continuous support help you improve processes, take corrective actions, and maintain quality.

Conclusion

During Production Inspection uncovers production problems at a rather early stage. We will assist you in validating the products being produced, ensuring they consistently meet quality requirements.

GIS Inspection is a China During Production Random Inspection agency. We provide independent quality control designed to protect your business interests. We have set up a network of 100+ full-time inspectors around China and Southeast Asia. Our highly trained and experienced inspectors are product experts who receive regular training in their field of specialization.

Our quality inspections can be carried out on all types of consumer products including apparel, footwear, furniture, toys, handbags and luggage, housewares, lighting, outdoor products, electronics and more.

GIS offers Pre-Production Inspection, During Production Inspection, and before delivery inspection to assess products Pre-Shipment Inspection. Contact our quality assurance experts to customize your inspection requirements now.

Read more about our quality control and quality assurance inspection service:

More Services

GET A QUOTE

During Production Inspection