Pre shipment Inspection is crucial for maintaining high standards of quality, ensuring customer satisfaction, and protecting businesses from risks associated with poor product quality. GIS Inspection ensures quality conformity, compliant, defect-free products with our quality assurance Pre shipment Inspection service in the global supply chain.

What is Pre-shipment Inspection?

Pre-shipment Inspection (PSI) also called Final Random Inspection, is a vital quality control process conducted by third-party inspection companies on behalf of buyers, importers, or manufacturers.

It generally takes place in the manufacturer’s premises or at the harbor on samples randomly selected according to the defined statistical sampling procedure ISO 2859-1 or otherwise agreed with the customer.

Pre shipment inspection criteria normally cover quantity, product conformity, safety, function, product labeling, carton markings and safety hints, and quality (consistent workmanship) compliance with the agreed specification to ensure that the products being shipped comply with the agreed-upon specifications, quality standards, and regulatory requirements.

Pre-shipment inspection is suitable for nearly all types of consumer goods purchased in Asia. The final inspection report is typically used by the importer to authorize shipment and trigger payment.

Learn more: Pre-Shipment Inspection (PSI): Everything You Need to Know

What are the Benefits of Pre-shipment Inspection?

The psi inspection is one of the most common third-party quality inspection services conducted by importers to verify the quality of your products before they are shipped. The benefits of pre-shipment inspection include:

- Quality Assurance

Pre-shipment inspection verifies that products meet the desired quality standards, specifications, and conform to any legal or regulatory requirements. It helps identify any defects or non-conformities early on, preventing the shipment of substandard goods.

- Risk Mitigation

Pre-shipment inspection can prevent costly returns, replacements, or legal issues that may arise due to defective or non-compliant products. By identifying issues before shipment, PSI helps avoid delays at customs due to quality or regulatory concerns.

- Compliance and Regulatory Adherence

Pre-shipment inspection verifies that products comply with relevant industry standards, regulations, and safety requirements. By ensuring compliance, PSI helps avoid legal penalties and fines that may result from non-compliant products.

- Deliveries Timely

An effective pre-shipment inspection can help ensure that products are shipped on schedule, avoiding any unforeseen delays caused by non-compliant goods. By identifying and addressing any issues before shipment, the inspection process aids in maintaining the agreed-upon delivery timeline.

What is the Procedure of Pre-shipment Inspection?

When should a shipment be inspected for quality? Normally, when 100% products have been completed and 80% are packaged, a pre shipment inspection company in China and Asia will visit the factory to test the quality of parts before shipment.

The quality assurance pre-shipment inspection ensures that the products meet quality standards before shipment, ultimately protecting both buyers and suppliers.

There are 10 important procedures that GIS pre-shipment inspection service performance:

1. Prepare work

Confirm inspection date, sampling method, product checklists, and inspector.

2. Opening Meeting

Have an opening meeting with factory.

3. Quantity Verification

Count products and shipping cartons to verify that the correct quantity of an order has been finished.

4. Random Sampling

Select a sample size according to the statistical sampling procedure ISO 2859-1.

5. Product Check

Verify that the products conform to the specifications against PO, photos, and sample.

6. Workmanship Check

Conduct a visual check for any damages and flaws in workmanship.

7. Function and Safety Test

Test to ensure that it functions properly and meets safety standards.

8. Packaging Check

Check the packing method and packing information to ensure that everything is accurate and safe for transportation.

9. Close Meeting

Have a close meeting to get factory’s confirmation.

10. Inspection Report

After completing the inspection, GIS Inspection will provide you with detailed and unbiased inspection reports and certificates, verifying whether the products meet the specifications stated in your contract.

Pre-shipment inspection procedure pdf

Learn more: 12 Essential Steps of Pre-Shipment Inspection: A Complete Guide to Quality Assurance

Pre-shipment Inspection Checklists

A comprehensive PSI inspection checklist is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

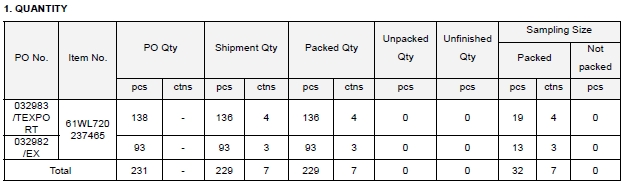

1. Quantity Verification

GIS inspectors count products and shipping cartons to verify that the correct quantity of an order has been finished which including PO quantity, shipment quantity, packed quantity, unpacked quantity, and unfinished quantity.

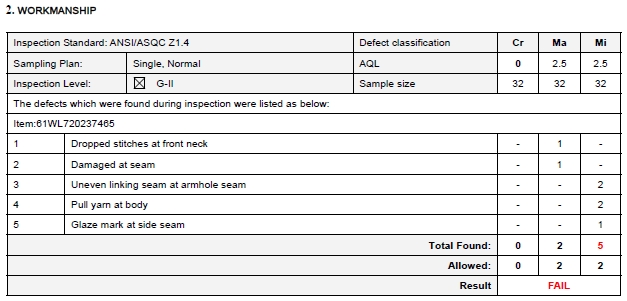

2. Workmanship Check

The most important and lengthy part of a pre-shipment inspection is the check of workmanship quality. The inspector will select a sample size according to the statistical sampling procedure ISO 2859-1, and conduct a visual check for any damages and flaws in workmanship and classify them as major, minor, or critical defects.

3. Product Description

GIS Inspection will verify that the products conform to the specifications against PO, photos, and sample.

4. On-site Check

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards. This includes various tests such as pull tests, fatigue tests, and stretch tests for apparel and garments, and safety tests for electronics and mechanical products.

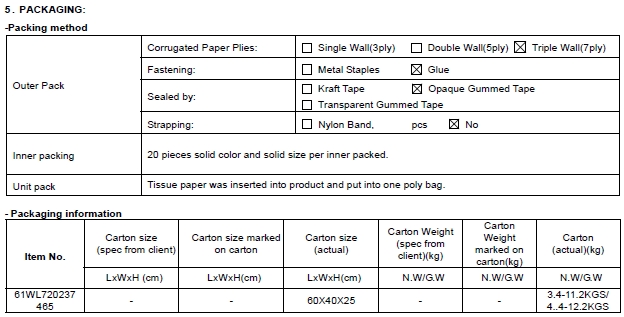

5. Packaging Check

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

Ready to get started on finding your reliable third-party quality inspection agency?

Click here to discuss and get a quote on final random inspection

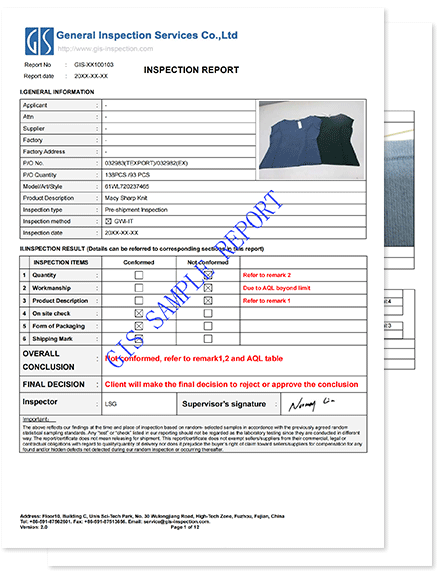

A Pre-shipment Inspection Report

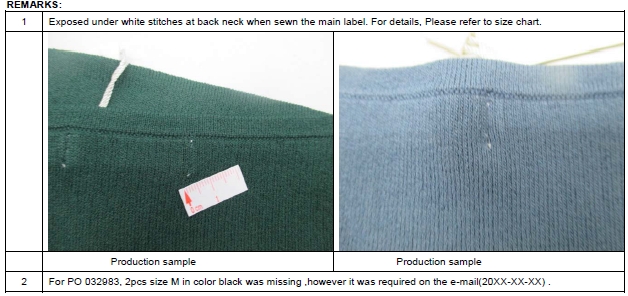

Once a pre-shipment inspection is completed, a report is compiled with a conformed/Not conformed result. Along with the result are an overview of key findings, a detailed account of the inspection results and supporting pictures.

The pre-shipment inspection report is one that the buyer must take into account to decide if the quality of the goods is acceptable. Also, some corrective actions should be implemented in collaboration with the manufacturer. The inspector is required to perform the draft quality inspection report to the manufacturer to recognize the quality problems encountered during the inspection.

A pre-shipment inspection by GIS Inspection will give you expert insight before the production begins giving you the safety and quality network and the confidence that your suppliers will offer you products of the highest quality, which favors the values of your brand.

DOWN A QUALITY INSPECTION SAMPLE REPORT

GIS Inspection detailed inspection reports and continuous support help you improve processes, take corrective actions, and maintain quality.

Conclusion

The PSI inspection aims to visual check on all the relevant aspects of the product: quantity, components, assembly, aesthetics, function, size, labeling, packaging, and other required parameters.

GIS will ensure that your products be safe, quality, and in compliance with local regulations. A full and detailed inspection report, together with a photographic record within 24 hours of the inspection allows you to see the work undertaken.

With 100+ full-time inspectors around China and Southeast Asia, GIS offers Pre-Production Inspection, During Production Inspection, and before delivery inspection to assess products Pre-Shipment Inspection.

GIS (General Inspection Service) is one of the best pre shipment inspection company in China, contact our quality assurance experts to customize your inspection requirements now.

Read more about our quality control and quality assurance inspection service: