In over 90% of cases, quality control inspection agencies conducting random sampling AQL inspections rely on the standard ISO 2859 for guidance. The inspector can simply use the ISO 2859 master tables, often referred to as AQL tables, to calculate the sample size and the AQL limits.

How to Read the AQL Table?

The AQL tables are incorporated into international quality standards to help ensure product quality meets your expectations. ISO 2859 consists of 2 tables: sample size code letters and single sampling plans.

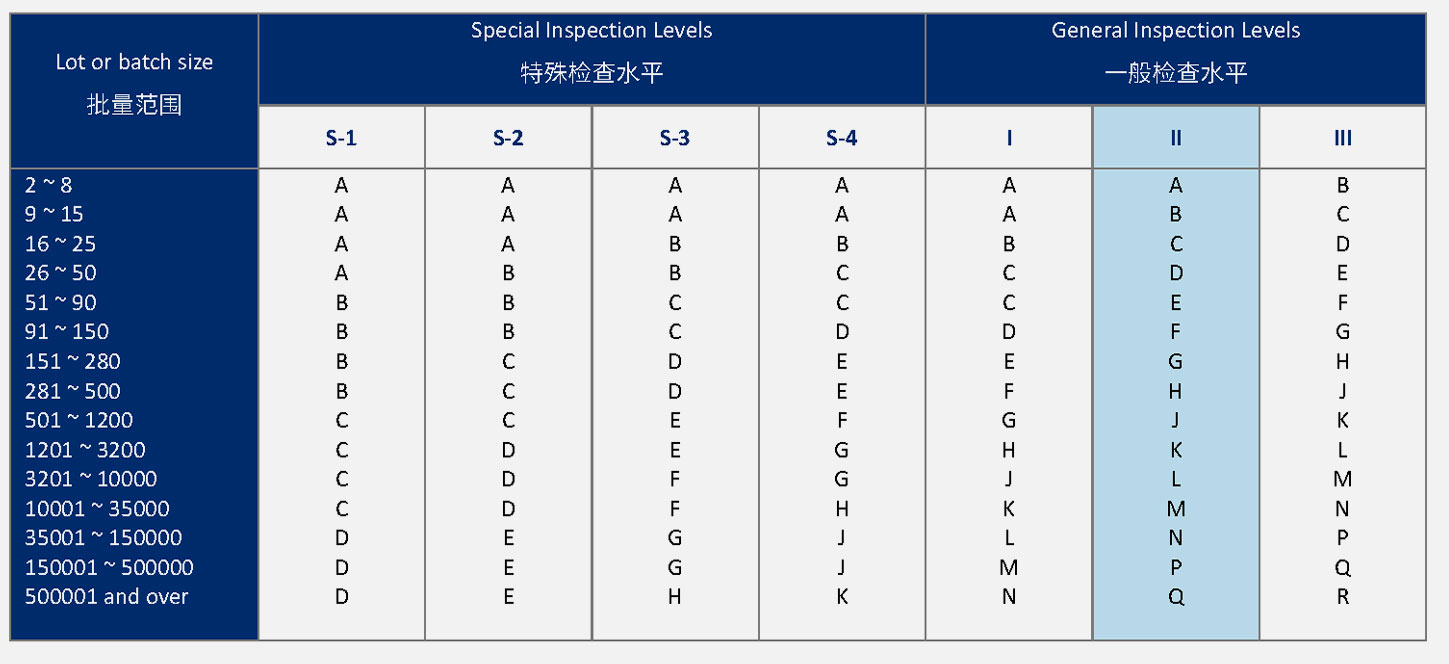

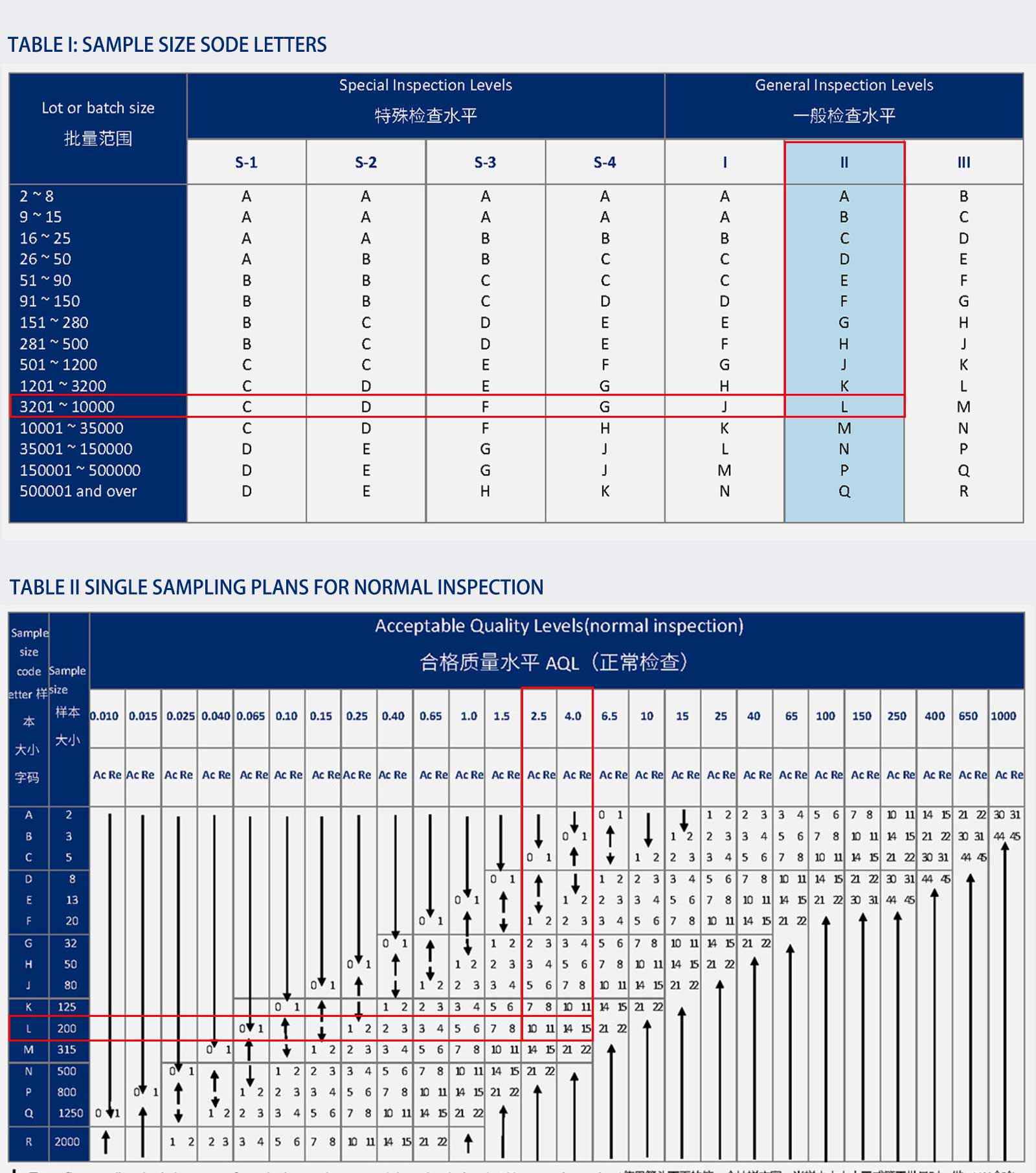

TABLE I: SAMPLE SIZE SODE LETTERS

The first table lists all the different sample size codes (A, B, D...) based on 2 inputs: The “inspection levels” and the “lot or batch size”.

There are 7 levels, and from the left to the right, the number of samples to be pulled out for inspection keeps increasing. There are 4 Special inspection levels (S1 to S4) and 3 general inspection levels (G1 to G3). Using this table, you can determine the sample size code which will be used next step in AQL table 2.

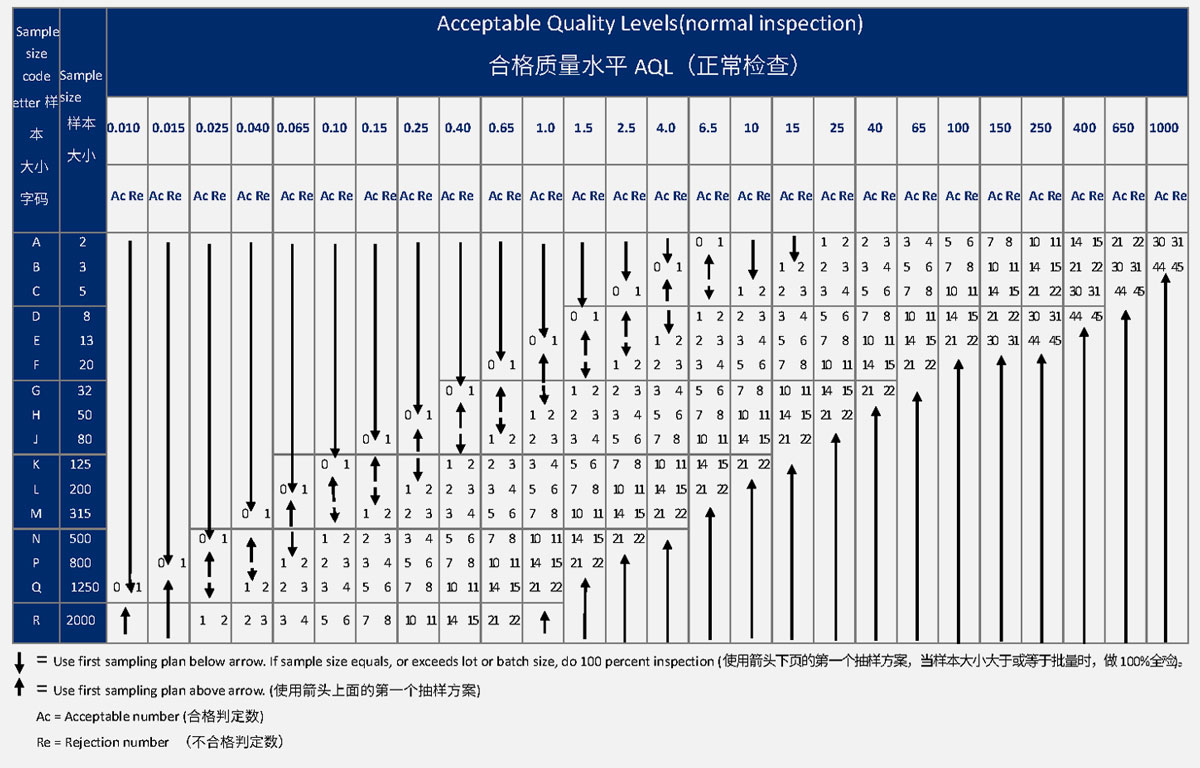

TABLE II SINGLE SAMPLING PLANS FOR NORMAL INSPECTION

The second table lists various sample sizes (top to bottom - 2 to 2000) and the acceptance and rejection numbers against the various AQLs (left to right - 0.065 to 1000). Using this table, you can determine the maximum number of defective products you can accept in your lot.

For example:

If the batch to check contains 5,000 pcs, the client inspection sampling level is General Level II and the AQL is 2.5 ,4.0.

If the batch to check contains 5,000 pcs, the client inspection sampling level is General Level II and the AQL is 2.5 ,4.0.

Step 1: Get the correct sample size code by using the first AQL table

l The shipment quantity is 5,000 pcs. Refer to the ‘Lot or batch size’ column on the left side of Table 1 and select the appropriate range. In this case, the correct lot size is 3,201 to 1,000.

l Select the inspection level, which determines how many products the inspector should check. In this case, the inspection level is ‘General Inspection Level II’.

l Look for the intersection of the ‘Lot or batch size’ row with the ‘General Inspection level II’ column. This will give the ‘Sample size code letter’, which in this case is ‘L’.

Step 2: Calculate the sample size and the acceptable quality limits by using the 2nd AQL table

l Find the ‘Sample size code letter’ on the left and the simple size number is 200. So, quality inspectors will need to randomly pick 200 pics out of the total shipment quantity of 5,000.

l Next, look for the intersection of the ‘Sample size’ row with the ‘Acceptable Quality Level’ column. It gives the acceptance and rejection numbers. The client has set AQL at 2.5 for major defects and 4.0 for minor defects.

Therefore, here are the limits: the products are accepted if NO MORE than 10 products with major defects AND NO MORE than 14 products with minor defects are found. For example, if you find 15 products with major defects and 12 products with minor defects, the products are refused. If you find 3 with major defects and 7 with minor defects, they are accepted.

Key Parameters You need to Know about AQL

1. Acceptance Quality Limit AQL

quality level that is the worst tolerable process average when a continuing series of lots is submitted for acceptance sampling

2. Lot Size:

Lot size is defined as number of items in a lot in ISO 2859 Sampling procedures for inspection by attributes. If you ordered different products, consider each product as a separate lot. (The quantity of each product is the lot size). If you ordered only one product, the lot size is the total batch quantity.

3. sample size:

Number of items in the sample.

4. Inspection Level:

Determines the sample size to inspect. Common levels include:

l General Inspection Levels (I, II, III):

Ø Level I: Has this supplier passed most previous inspections? Do you feel confident in their products quality? Instead of doing no quality control, buyers can check fewer samples by opting for a level-I inspection.

However, settling on this level by default, in order to spend less time/money on inspections, is very risky. The likelihood of finding quality problems is lower than generally recommended.

Ø Level II: It is the most widely used inspection level, to be used by default.

Ø Level III: If a supplier recently had quality problems, this level is appropriate. More samples are inspected, and a batch of products will (most probably) be rejected if it is below the quality criteria defined by the buyer.

Some buyers opt for level-III inspections for high-value products. It can also be interesting for small quantities, where the inspection would take only one day whatever level is chosen.

l Special Inspection Levels (S-1 to S-4): Used for smaller sample sizes or specific tests.

5. The AQL limits

Quality level that is the worst tolerable process average when a continuing series of lots is submitted for acceptance sampling. The AQL limits appropriate for your market. If your customers accept very few defects, you might want to set a lower AQL for both major and minor defects.

6. AQL Defects:

The maximum allowable number of defects per hundred units. Generally speaking, the three types of defects are interpreted in the following ways:

l Critical defects: a defect that fails to meet mandatory regulations and/or affects the safety of consumers/end users.

l Major defects: a defect that leads to product failure and reduction of product’s usability or sale ability to a large extent.

l Minor defects: a defect that shows deviation from quality standard but is not likely to reduce the usability or sale ability of the product.

GIS Inspection Support your Quality Assurance

Booking your product inspection via GIS. We help to select your inspection level and AQL. GIS shows you the sample quantity and the acceptable level of each type of defect in your order. Our inspector will perform the inspection according to your requirements.

GIS Inspection offers a variety of Quality Control services, such as Product Inspection, Factory Audit, and Lab Testing in Asia.

Feel free to visit our website (www.gis-inspection.com) to get to know more about our company and services, and should you have any questions, please feel free get in touch with us at service@gis-inspection.com.