What are soft goods? What are the key inspection criteria for soft goods? Soft goods are mostly consumer goods such as clothing, textile, shoes, bags, and fashion accessories.

In this blog, we explore the key inspection criteria for softgoods, each criterion of the inspection plays a vital role in ensuring that the product meets customer expectations and compliances regulations.

Quality control (QC) in soft goods supply chains involves a series of systematic processes to ensure that products meet specified quality standards before they reach the market. These processes include inspection, testing, and verification at various stages of production and distribution.

The key inspection criteria for soft goods including: materials, workmanship, colors, style, accessories, weight, measurements, labeling and hangtags, assortment, markings.

1 Materials

A lot goes into inspecting materials for your soft goods like garment. While some may tend to purchase things at a lower price, this will ultimately cost more in the long term if the materials are of poor quality.

Inspectors evaluate the quality of textile materials, checking for defects, flaws, and consistency in weave or knit. Ensuring the fabric meets specified standards for strength, texture is essential for garment performance and customer satisfaction. It’s well worth spending extra money on material inspection.

2 Workmanship

The visual inspection of workmanship is one of the most essential components of softgoods quality control. Since these products are often judged by their appearance, any visible defect can lead to customer complaints or returns. For example, for garment, check on the overall workmanship of the selected garment pieces to identify defects like double stitches, untrimmed threads, and wrinkle marks.

At GIS Inspection, our inspector will evaluate the overall workmanship of the products, looking at aspects such as appearance, cleanliness, workmanship, color fading, and so on. Any defects found will be categorized as critical, major, or minor.

3 Colors

The color inspection is intended to determine whether the color match the sample swatches, reference sample or color chart. The various components (e.g. of a shirt, blouse, pants etc.) must be of the same shade. For piece-goods, is the shading of the dye of the printing uniform throughout? What is the ratio of different shade lots?

4 Style

A style check verifies that the correct product style is being produced and shipped, ensuring consistency with the buyer's order and avoiding costly returns due to wrong or mismatched items.

5 Accessories

The importance of inspection for soft goods accessories cannot be overstated, as these small components play a critical role in the overall quality, functionality, safety, and brand reputation of the finished soft good product.

For example, accessories like zippers, buttons, buckles, and snaps must function flawlessly. Sharp edges on a metal buckle could cause injury, or small, detachable parts on children's soft goods could be a choking hazard. Inspections help identify and eliminate such dangers.

6 Measurements

For garments, as a guideline, 10-20% of the sample size must be measured (at least 3 per size) in accordance with the measurement specifications and tolerances provided by the client. If the client has not specified any particular tolerances for the measurements, tolerances indicated on the Measurement Tolerance Sheet will be applied.

Checkpoints for data measurement can be various for different garment types. Take a sports shirt for example, here are some key measurement points that this session will cover:

- Body length for front and back

- Chest

- Neck width

- Front neck drop and back neck drop

- Shoulder

- Sleeve length

- Sleeve opening

- Placket width

- Shoulder forward

- Collar stand height

- Collar point length

For fabrics, the measuring can be done with fabric inspection machine. Fabric inspection uses a numerical designation for the grading of fabrics from a visual inspection. Normally, it’s also called fabric inspection 4-point or 10-point system. 4-point system is taken a priority to be used for third-party inspection agency. 10-point system is only to be used once it is requested by client.

Learn more about fabric quality inspection: https://www.gis-inspection.com/product/fabric-quality-control-inspection

7 Assortment

The assortment check is also important. Large retail chain stores distribute standard packed items to their numerous sales outlets, e.g. a master carton will contain 50 red, 50 black, 30 green and 20 blue ones. Some unscrupulous manufacturers, for lack of a specified color or size, may be tempted to make up the shortage by some other colors or sizes.

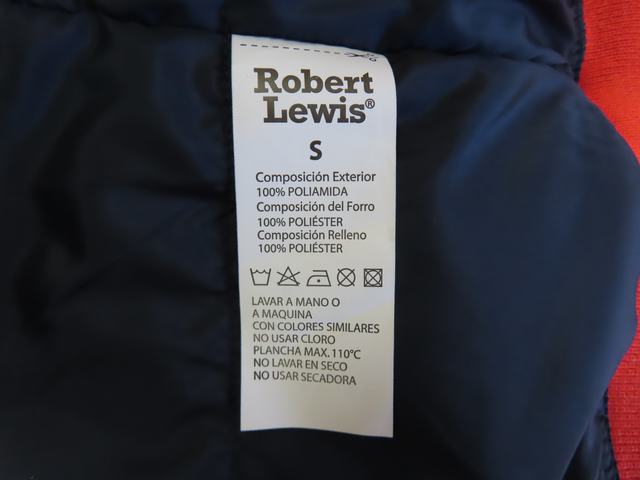

8 Labeling and Hangtags

Most articles are provided with a label or a hangtag. Some countries have stringent laws regarding the compulsory labeling of articles.

According to the U.S. Federal Trade Commission (FTC), garments entering the U.S. market must have a care label that includes at least the following information:

- Fiber content (e.g. Cotton)

- Country of origin (e.g. Made in China)

- Washing and care instructions (e.g. Hand Wash)

- Manufacturer Identification, which is a Registered Identification Number (RN)

The European Economic Community (EEC) compulsorily stipulates that all imported articles show the fiber composition of fabrics and garments.

Brands and manufacturers must ensure that care labels meet requirements regarding placement, size, and font. During inspection for quality, the checking of the labels must not be neglected.

9 Markings

External markings on cases/cartons/boxes/bales should comply with client’s particular requirements. In certain case the buyer insists on neutral packing which means that manufacturer’s/supplier’s name and country are not shown.

FAQs

Q1: What are Soft Goods?

Softgoods are products that are literally soft and less durable. These products are typically sold in high volumes through retail and e-commerce platforms, making quality control critical to brand reputation, customer satisfaction, and regulatory compliance.

Here are types of soft goods:

- Apparel and Garment

- Textiles

- Fabric

- Luggage and Bags

- Footwear

- Fashion Accessories

- Soft toys

- Baby and Children clothing

- Home Textile

Q2: How to Start Inspection for Soft Goods with GIS Inspection

With over 20 years of dedicated experience in the quality control industry, General Inspection Service(GIS)brings a wealth of expertise specifically tailored to softgoods(quality control.

Our comprehensive knowledge spans across various softgoods types, from apparel and garment, to textiles, fabric, luggage and bags, footwear, fashion accessories, soft toys, baby and children clothing, home textile, and beyond.

Situated strategically in key softgood manufacturing hubs such as China, India, and Vietnam, our trained inspectors ensure prompt response and thorough inspections, reaching your supplier's factory within 48 hours.

Our informative report with detailed images can provide you with a thorough review of your products manufactured overseas and support you in making informed decisions on production and shipment.

As a third-party inspection company with intelligent management for quality assurance, GIS Inspection aims to build the world’s most influential third-party inspection service center.

Try GIS Inspection today to find out how we can help to improve your products quality.

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.