China | Vietnam | Malaysia | India

GIS Inspection offers quality control, product inspection, and factory audits services in China to help brands and importers ensure products quality, safety, and compliance throughout their supply chain.

Founded in 2005, GIS Inspection is a global Quality Assurance and Quality Control company in China and has a professional technical team with strong expertise in quality assurance and a CS team to offer timely service.

Our quality control inspectors and auditors deliver quality assurance and quality control services across China, operating in all major cities and industrial centers, including Guangdong, Fujian, Zhejiang, shanghai, South of Jiangsu, Zhengzhou city, Tianjin city, and Beijing city.

Why Performance Quality Control Inspection When Importing from China

China has established itself as the world's leading manufacturing hub and largest goods exporter. With its competitive production costs, huge labor pool, established supply chains, and extensive business ecosystem, China has been called "the world factory”.

As the world’s largest manufacturing nation, China is a primary source of goods for many retailers, brands, and importers worldwide. It is also extremely crucial for buyers to ensure that your goods meet requirements and fully comply with industrial regulations and standards.

And these are just some of the ways quality inspection could have solved problems. Here are some key reasons why QC inspections are essential:

1. Prevent Defective Products

QC inspections help identify any defects or inconsistencies early, allowing you to catch issues before products reach your customers.

2. Ensure Compliance with Specifications

Performance QC checks ensure that your products align with your precise requirements, from design and materials to functionality and verify compliance with safety, health, and regulatory standards.

3. Improve Supply Chain Efficiency

Inspections allow you to catch and resolve issues early, preventing unexpected disruptions in your supply chain. Avoiding delays caused by quality issues keeps your production and distribution schedules on track.

4. Protect Brand Reputation

Quality inspections reduce the risk of poor reviews, complaints, and damage to your brand image due to subpar products.

Hiring a professional third-party inspection agency in China is one of the best ways to ensure that your product safety and meets your requirements. It keeps your suppliers in check, your orders shipping on time and, ultimately, ensures customer satisfaction, avoids expensive product recalls.

Types of third-party inspection and Audit services provided by GIS Inspection in China

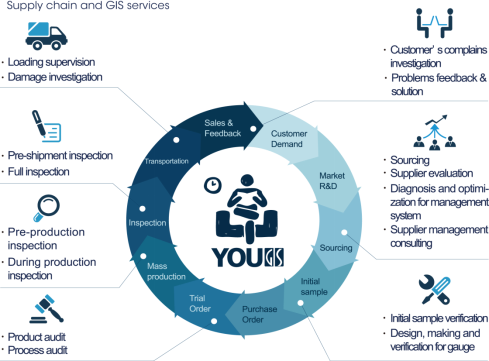

GIS offers a comprehensive QC service including product inspection services(IPC, DUPRO and PSI), container loading supervision, supplier management and development, lab testing and more.

There are mainly 5 types of inspection in quality control assess the quality of products, ensuring consistent production processes and effective control systems:

The main 5 types of third-party inspection and audit services provided by GIS:

- Pre-Production Inspection(PPI)

- During Production Check (DUPRO)

- Pre-shipment Inspection (PSI)

- Loading Supervision (LS)

- Factory Audit

Read more here: Quality Control Inspection Company in China to learn how choose to conduct product inspection.

These five types of inspection is carried out at a different stage of product manufacturing process. Based on your specific requirements and industry, you may find that one or all of these five inspection types are of the essence.

1. Pre-Production Inspection(PPI)

Pre-Production Inspection (PPI) takes place at the beginning of the production process or even before the start of manufacturing to assess the quantity and quality of the raw materials and components, and whether they are in conformity with product specifications.

It is the first step in ensuring that your supplier will consistently manufacture good quality products, which is used to identify quality issues early on in production and to prevent them from causing bigger issues further down the track.

By conducting an Pre-Production Inspection, buyers can proactively address any issues early in the production process, minimizing the risk of defects, delays, and quality problems in the final product.

2. During Production Check (DUPRO)

During Production Check (DUPRO) is conducted when 30%-50% of goods are completed so that to ensure consistent quality in the manufacturing process. Its purpose is to check that the factory follows the original specifications correctly and that the output is still on schedule.

DUPRO (During production inspection) can help to detect and correct any issues or defects that could affect the quality or delivery of the products.

3. Pre-Shipment Inspection

Pre-Shipment Inspection(PSI, known as Final Random Inspection) is the most popular and commonly used quality inspection method. Pre-Shipment Inspection takes place when the production is 100% completed. Pre-Shipment Inspection can visual check on all the relevant aspects of the product: quantity, components, assembly, aesthetics, function, size, labeling, packaging, and other required parameters.

Pre-Shipment Inspection is an important step in the quality control process that ensures the production complies with the specifications of the buyer.

4. Loading Supervision (LS)

Loading Supervision (LS) is the final but crucial step in the quality control process that is properly preparing batches for shipping to destination markets.

Container loading inspections is usually performed at the factory, forwarders port to verify count to ensure your products are loaded correctly. Inspectors will supervise throughout the whole process and ensure your products are handled professionally to guarantee their safe arrival to their final destination.

Also, this inspection confirms products are consistent with the packing list of the client, ensures the correct amount of different styles, sizes, quantities, and verifies all the product information, and packaging compliance.

5. Factory Audit

A Factory Audit is a process of assessing and evaluating a supplier’s operations, processes, quality control systems, legality, compliance with regulations, and overall reliability of a potential or existing supplier.

Approving the factory where production will take place is the last step in the process of selecting a supplier. Conducting Factory Audits allows you to ensure that you are working with legit vendors who can provide a consistent supply of high-quality materials and adhere to internationally recognized standards.

GIS Quality Inspection and Audit Service Coverage

As a leading third-party quality control agency in China, GIS Inspection has extensive expertise in product inspections, factory audits, and supplier management services for a wide range of products, including:

- Electric Products: household electric & electronic products, audio/ video products, electronic equipment, computer device, lights and lighting, components, telephony, other electric &electronic products.

- Soft Goods: garment, footwear, home textile, fabric, bag and suitcases, and many more.

- Hard Goods: handicraft, household product, furniture, toys, building and house furnishing product, sports, ceramic products, stone products, other hard goods.

- Mechanical Products: electromechanical device, machine parts, auto parts, pump, mould, machining parts, die casting, stamping parts, other machinery product.

- Chemical Products:chemical raw materials and chemical products, chemicals and additives, fertilizer and compound fertilizer, household chemical product.

- Food: cans, aquatic products, flavorings, others.

GIS Quality Control and Inspection Service Network and Cost in China

No matter how long you’ve worked with a particular supplier and how much you trust them to manufacture the product you want, you can never truly be sure of what you’ll get without seeing it. And that’s why most experienced importers insist on product inspection before shipping.

We have established a wide network of local offices throughout China, including major cities such as Guangdong, Fujian, Zhejiang, shanghai, Jiangsu, Zhengzhou, Tianjin city, Beijing city, and Hong Kong. These offices, along with our numerous operational hubs across the country, allow us to provide comprehensive support and services to clients throughout China.

GIS Inspection operates in China to help overseas buyers select suppliers with confidence through factory audit and overcome problems in product quality with product inspections and loading supervision, while offering the advantage of a completely standardized quality control process with full-time inspectors and auditors only.

Quality Control Inspection services rate:

All inclusive: 150 USD/Man-day (Guangdong | Fujian | Zhejiang | shanghai | South of Jiangsu | Zhengzhou city | Tianjin city | Beijing city)

Factory Audit services rate:

All inclusive: USD 200 / Man-day (Guangdong | Fujian | Zhejiang | shanghai | South of Jiangsu | Zhengzhou city | Tianjin city | Beijing city)

Other Cities:

Total fee = inspection fee + traveling fee + hotel fee if necessary

Note:Third Party Inspection Company charges for per man per day.

MAN-DAYS DEFINITION

This general man-day definition: "a unit of one day's work by one person" seems to be the most suitable for all cases. In the quality control industry the man-day is considered as a workload unit, which is very similar. From the buyer's point of view, the "man-day" is a system that allows direct and quick QC cost calculations.

"Man": both women and men work as inspectors. Qualified staff is crucial for reliable quality control. Inspectors spend their time checking products quality and conformity in factories in order to protect the importers' interests.

"days": A meaningful inspection takes four to six hours. Inspectors should only perform one QC per day, to ensure reliable results.

4 Reasons Why Global Buyers Choose GIS Inspection to Conduct Quality Inspection

At GIS Inspection, we provide world-leading quality control services both in China and globally. We have a keen focus on various product consumer product categories, including but not limited to home appliances, furniture, outdoor goods, electronics, textiles, garments, toys, footwear.

- Accredited by: CNAS against ISO 17020&17025, CMA certificate, Certificate of qualification for institution of import & export commodity inspection and survey, China entry-exit inspection and quarantine association import and export commodity inspection and survey organization branch member certificate.

- A dedicated CS will be assigned to follow up your inspection request from start to end to ensure a smooth communication.

- Highly competitive and all-inclusive rate as per country without charging additional travel costs.

- Comprehensive inspection reports, replete with images and inspection records, offer a transparent view of the product quality.

Contact us now for more information about quality control or supplier assessment in China.

GIS Inspection Enhances your Company’s Quality Management

Product inspections play a crucial role in reducing product returns due to defects or poor quality, which can significantly impact your profit. By choosing the right inspection service, you can effectively reduce return rates, maintain profitability, and ensure customer satisfaction.

General Inspection Service (GIS Inspection) is the leading 3rd party quality control inspection service agency in China. We have been fully accredited by CAM, ISO 9001, CNAS17020, and AQSIQ. We provide a comprehensive QC service including product quality inspection services, container loading supervision, supplier management and development, lab testing and more.

GIS Inspection provides a highly specialized approach to quality control, with dedicated engineering teams focusing on specific product categories and requirements. This structure allows them to cater to diverse product needs and tailor quality programs to meet client expectations effectively.

Our QC teams cover most regions in China as well as many other three Asian countries including Vietnam, Malaysia, and India. Our quality inspection checks for quality and identifies ways to minimize manufacturing costs, reduce scrap losses and mitigate causes of defective work. Get in touch with us to learn more.