China | Vietnam | Malaysia | India

GIS Inspection provides leading quality control inspection and factory audit services in Vietnam ensuring product quality throughout your entire consumer goods supply chain.

GIS Inspection(General Inspection Service) is a third-party inspection agency in Vietnam. We offer a range of comprehensive quality assurance services for customers across the world.

These include quality control inspections, factory audits, supplier evaluation, industrial iroduct inspection, loading supervision, damage investigation, process audit, product audit, and supplier management and development services throughout Vietnam.

By integrating performance QC inspections and audits, you safeguard your investment, ensure compliance, and build a sustainable supply chain from Vietnam. This proactive approach helps you maintain high standards and navigate any regional complexities effectively.

Why Performance Quality Control Inspection and Audit When Sourcing from Vietnam

Vietnam has emerged as a prominent global sourcing hub, owing to its competitive manufacturing costs and diverse production capabilities. However, conducting meticulous performance quality control inspections is imperative to ensure successful outcomes. Here’s why:

1. Guaranteeing Product Quality: Verifies that products meet precise specifications and consistently maintain high quality; Reduces the risk of receiving defective or substandard goods.

2. Ensuring Supplier Reliability: Confirms that suppliers strictly adhere to agreed-upon production timelines and uphold their commitments towards product quality. - Strengthens confidence in establishing long-term supplier relationships.

3. Regulatory Compliance: Ensures that products comply with international safety and regulatory standards for target markets; Minimizes legal risks and complications related to import/export procedures.

4. Cost Control: Identifies defects at an early stage of production, resulting in cost savings on rework, recalls, and delays; Enhances over all production efficiency by proactively addressing potential issues upfront.

Hiring a professional third-party inspection agency in Vietnam is indeed an effective approach to maintaining product quality, safety, and compliance. It keeps your suppliers in check, your orders shipping on time and, ultimately, ensures customer satisfaction, avoids expensive product recalls.

Factory Audit and Supplier Assessment Services in Vietnam

A Factory Audit is a process of assessing and evaluating a supplier’s operations, processes, quality control systems, legality, compliance with regulations, and overall reliability of a potential or existing supplier.

Approving the factory where production will take place is the last step in the process of selecting a supplier. Conducting Factory Audits allows you to ensure that you are working with legit vendors who can provide a consistent supply of high-quality materials and adhere to internationally recognized standards.

A supplier or factory audits in Vietnam is a cost-effective way to mitigate the risk of engaging with legitimize businesses and non-compliance with quality requirements. By conducting a factory audit, you can identify risks associated with the supplier or factory before making a deposit.

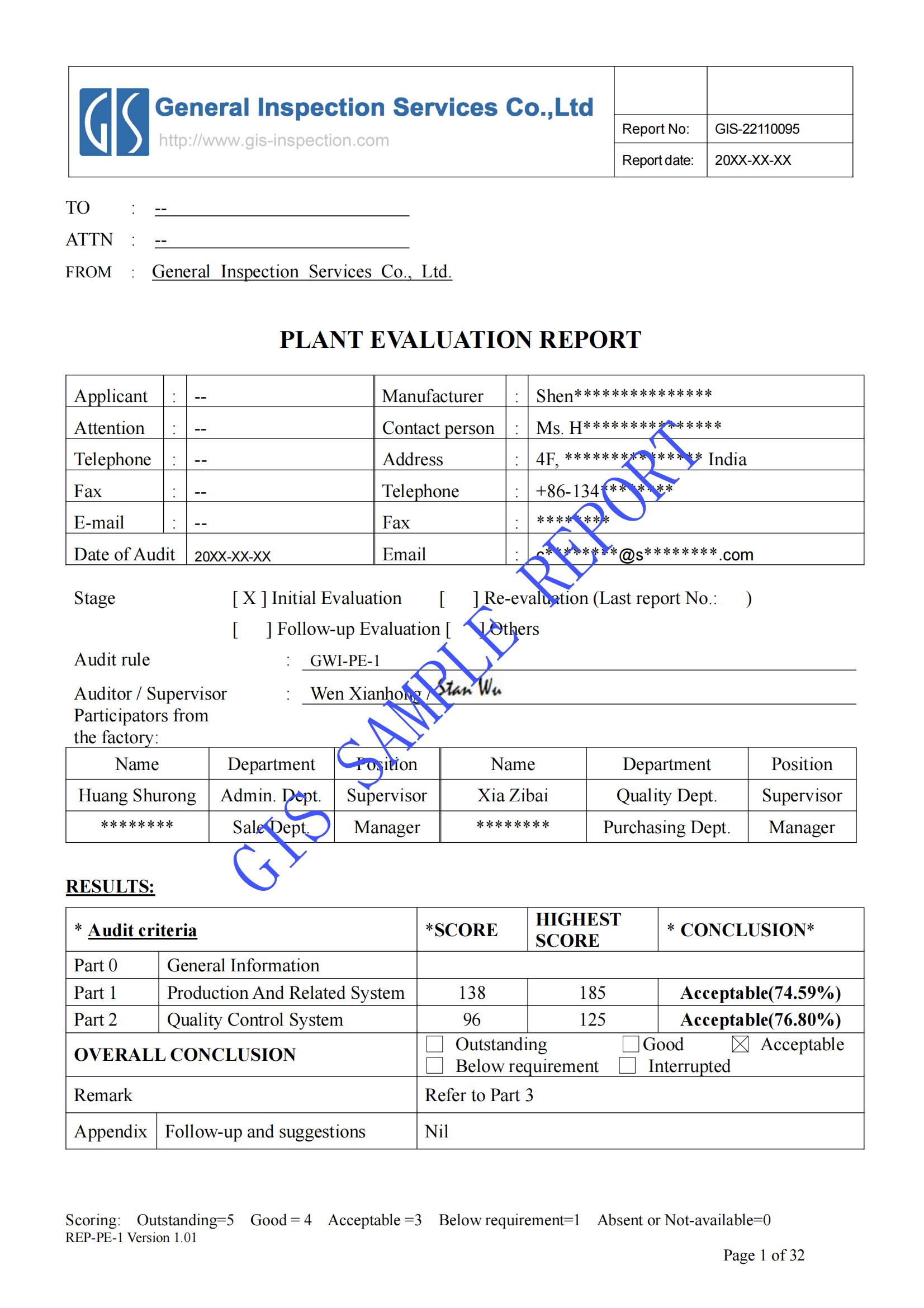

When conducting factory audits, a comprehensive checklist is critical for ensuring that your quality management systems followed correctly. GIS supplier audits cover the following major checkpoints:

• Basic Information.

• Production and related system.

• Quality control.

Learn more about Factory Audit.

Check a Factory Audit in Vietnam sample report.

Products Quality Control Inspection in Vietnam

A key approach in quality control management involves performing on-site product inspections before shipping them from Vietnam to the intended market.

We also offer inspection services throughout the manufacturing process, from raw material inspection to pre-shipment inspection. With our quality control services, you can be confident that your products are high quality and compliant with international safety standards

Pre-Production Inspection(PPI)

Pre-Production Inspection (PPI) takes place at the beginning of the production process or even before the start of manufacturing to assess the quantity and quality of the raw materials and components, and whether they are in conformity with product specifications.

It is the first step in ensuring that your supplier will consistently manufacture good quality products, which is used to identify quality issues early on in production and to prevent them from causing bigger issues further down the track.

By conducting an Pre-Production Inspection in Vietnam, buyers can proactively address any issues early in the production process, minimizing the risk of defects, delays, and quality problems in the final product.

During Production Check (DUPRO)

During Production Check (DUPRO) is conducted when 30%-50% of goods are completed so that to ensure consistent quality in the manufacturing process. Its purpose is to check that the factory follows the original specifications correctly and that the output is still on schedule.

DUPRO (During production inspection) can help to detect and correct any issues or defects that could affect the quality or delivery of the products.

Pre-Shipment Inspection

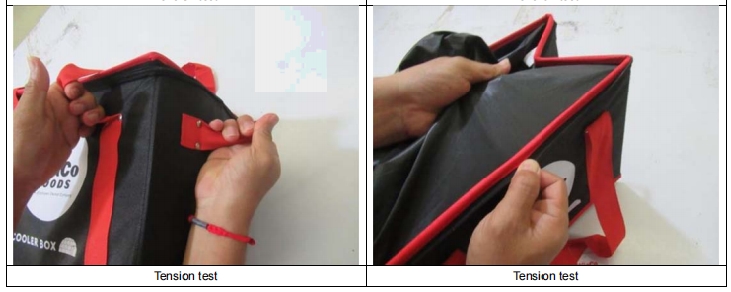

Pre-Shipment Inspection(PSI, known as Final Random Inspection) is the most popular and commonly used quality inspection method. Pre-Shipment Inspection takes place when the production is 100% completed. Pre-Shipment Inspection can visual check on all the relevant aspects of the product: quantity, components, assembly, aesthetics, function, size, labeling, packaging, and other required parameters.

Pre-Shipment Inspection is an important step in the quality control process that ensures the production complies with the specifications of the buyer.

Loading Supervision (LS)

Loading Supervision (LS) is the final but crucial step in the quality control process that is properly preparing batches for shipping to destination markets.

Container loading inspections is usually performed at the factory, forwarders port to verify count to ensure your products are loaded correctly. Inspectors will supervise throughout the whole process and ensure your products are handled professionally to guarantee their safe arrival to their final destination.

Also, this inspection confirms products are consistent with the packing list of the client, ensures the correct amount of different styles, sizes, quantities, and verifies all the product information, and packaging compliance.

GIS Quality Inspection and Audit Service Coverage

As a leading third-party quality control agency in Vietnam, GIS Inspection has extensive expertise in product inspections, factory audits, and supplier management services for a wide range of products, including:

- Electric Products: household electric & electronic products, audio/ video products, electronic equipment, computer device, lights and lighting, components, telephony, other electric &electronic products.

- Soft Goods: garment, footwear, home textile, fabric, bag and suitcases, and many more.

- Hard Goods: handicraft, household product, furniture, toys, building and house furnishing product, sports, ceramic products, stone products, other hard goods.

- Mechanical Products: electromechanical device, machine parts, auto parts, pump, mould, machining parts, die casting, stamping parts, other machinery product.

- Chemical Products:chemical raw materials and chemical products, chemicals and additives, fertilizer and compound fertilizer, household chemical product.

- Food: cans, aquatic products, flavorings, others

GIS Quality Control and Inspection Service Network and Cost in Vietnam

GIS Inspections has been providing quality inspection and audit services in Vietnam for years. Our network of quality control inspectors is located in key exporting cities across Vietnam and can perform inspections on-site within 24 hours and send you a detailed inspection report on the other work day.

Guaranteed all-inclusive price of 299 USD per man-day for pre-shipment inspection in Vietnam manufacturing regions. GIS Inspection team in Vietnam will devise a quality inspection plan and find quality control solutions to the supply chain. We ensure that your goods meet all regulations and requirements.

4 Reasons Why Global Buyers Choose GIS Inspection to Conduct Quality Inspection

At GIS Inspection, we provide world-leading quality control services both in Vietnam and globally. We have a keen focus on various product consumer product categories, including but not limited to home appliances, furniture, outdoor goods, electronics, textiles, garments, toys, footwear.

- Accredited by: CNAS against ISO 17020&17025, CMA certificate, Certificate of qualification for institution of import & export commodity inspection and survey, China entry-exit inspection and quarantine association import and export commodity inspection and survey organization branch member certificate.

- A dedicated CS will be assigned to follow up your inspection request from start to end to ensure a smooth communication.

- Highly competitive and all-inclusive rate as per country without charging additional travel costs.

- Comprehensive inspection reports, replete with images and inspection records, offer a transparent view of the product quality.

GIS Inspection Enhances your Company’s Quality Management

GIS Inspection is the leading 3rd party quality control inspection service agency in Vietnam. We empower buyers to confidently verify suppliers through comprehensive supplier evaluations and address product quality challenges via quality assurance inspection.

We provide a comprehensive QC service including product quality inspection services, container loading supervision, supplier management and development, lab testing and more.

Contact us now for more information about quality control and factory evaluation in Vietnam.