Tableware and Kitchenware | Furniture | Household and Home Decoration | Sporting Goods | Toys | Pet Products | Decoration Materials

Quality control of toy products is a critical part of ensuring children’s health and safety. Hundreds of thousands of toy-related injuries occur every year and these incidents can result in product recalls, lawsuits, and serious reputational damage.

Children’s health and safety are seriously endangered by non-compliant toy products. The safety of kids is a top priority, so toys must be safe. For all manufacturer, importer, and brands, ensuring the safety and quality control of toy products is essential.

During toy inspection, experienced quality control professionals examine the products to identify any potential safety hazards, such as choking risks, sharp edges, or loose parts. They also assess the quality of the materials used and check for compliance with relevant standards and regulations.

GIS Inspection is a leading third-party quality control agency in China. Our comprehensive toy inspection services are designed to help you meet regulatory standards, maintain product quality, and build consumer trust.

Toys Quality Control Inspection

Toys Quality Control Inspection is the process of checking and verifying toy products to ensure they meet quality, safety, functionality, and regulatory standards from manufacturing to being shipped.

Quality Control of Toy Products is a critical part of ensuring that the toys you bring to market meet the highest safety and quality standards. These standards are designed to protect consumers from potential dangers such as choking, suffocation, and injury.

Ensuring that your toys comply with local and international safety standards is not only a legal requirement but also critical for your brand’s reputation and trust with consumers.

At GIS Inspection, we provide a comprehensive range of factory evaluations and quality control inspections for the entire toy supply chain.

Different Types of Toys We Inspect

GIS Inspection provides manufacturers, retailers and importers with comprehensive customized Quality Assurance Solutions for all toy needs made of plastic, wooden, metal, plush, and electronic:

- Plush toys

- Dolls

- Ride-on toys

- Projectile toys

- Games

- Figurines

- Construction toys

- Creative art materials

- Puzzles

- Pull along toys

- Battery operated toys

- Radio controlled toys

- Infant toys

- Residential playground equipment

Schedule Your Toys Products Inspection Today!

By employing an independent inspection and testing partner like GIS Inspection, quality concerns will be identified and controlled at the very source.

The Importance of Toys Quality Inspection

Toys inspection plays a vital role in the toy industry by ensuring that toys meet the necessary standards for safety, durability, and overall quality. Safety is of utmost concern when it comes to toys, especially those designed for children.

Here are critical aspects to consider during toys inspection:

- Material Safety: Toys must be manufactured using safe and non-toxic materials that comply with international safety regulations. Inspectors assess the materials used in toy production to ensure they are free from harmful substances.

- Mechanical and Physical Properties: The structural integrity of toys is crucial to prevent choking hazards or injuries. Inspections include assessments of components like small parts, sharp edges, and potential breakage points to guarantee the toys’ safety during play.

- Design and Construction: The design and construction of toys impact their overall quality and appeal. Inspectors evaluate the design’s ergonomics, functionality, and aesthetics to ensure that the toys are both enjoyable and safe to use.

- Labeling and Age Grading: Proper labeling on toys is essential to inform consumers about age-appropriate usage and any potential hazards. Inspectors verify that toys are correctly labeled with age recommendations, safety warnings, and manufacturer

Regulations and Standards for Toys Quality Control

Toys quality control is essential to ensure that these products meet the safety standards and regulations, providing children with safety. Various international, regional, and national standards govern toys quality control, addressing factors such as safety, materials, design, and craftsmanship.

EN 71: safety requirements for toys in EU

The directive defines safety requirements that toys must comply with, covering aspects such as mechanical and physical properties, flammability, chemical composition, and specific hazards. These requirements aim to prevent potential risks and hazards associated with toys.

- EN 71-1: Mechanical and physical properties

- EN 71-2: Flammability

- EN 71-3: Specification for migration of certain elements

- EN 71-4: Experimental sets for chemistry and related activities

- EN 71-5: Chemical toys (sets) other than experimental sets

- EN 71-6: Graphical symbols for age warning labeling

- EN 71-7: Finger paints

- EN 71-8: Swings, slides, and similar activity toys for indoor and outdoor family domestic use

- EN 71-9: Organic chemical compounds – Requirement

- EN 71-10: Organic chemical compounds – Sample preparation and extraction

- EN 71-11: Organic chemical compounds – Methods of analysis

- EN 71-12: N-Nitrosamines and N-Nitrosatable Substances

- EN 71-13: Olfactory board games, cosmetic kits, and gustative games

- EN 71-14: Trampolines for domestic use

ASTM F963: Standard Consumer Safety Specification for Toy Safety

ASTM F963 is a mandatory consumer product safety standard for children’s toys in the USA. It covers various aspects of toy safety, including material, flammability, toxicology, electrical energy, sound, small objects, and hazardous edges. ASTM F963 also specifies labeling requirement, instructional literature, producer’s markings and testing methods.

Learn more: ASTM F963- Safety Standard for Toys in the US

CPSC Regulations

The U.S. Consumer Product Safety Commission (CPSC) sets regulations for toy safety in the United States, including toys. These regulations cover various safety aspects to prevent harm to children.

ISO 8124: International safety requirements for toys

The ISO 8124 standard applies to all toys (any product designed or clearly intended for use in play by children under 14 years of age). It specifies acceptable criteria for structural characteristics of toys, such as shape, size, contour, spacing (e.g. rattles, small parts, sharp points and edges, and hinge-line clearances) as well as acceptable criteria for properties peculiar to certain categories of toy .

It specifies requirements and test methods for toys intended for use by children in various age groups from birth to 14 years. It also requires that appropriate warnings and/or instructions for use be given on certain toys or their packaging.

Types of Third-party Toys Quality Control Inspection

Toys are subject to strict safety regulations worldwide due to their direct impact on children's health and development.

GIS Inspection’ network of qc provides strong expertise in many different fields, making the General Inspection Service uniquely placed to help manufacturers, importers and brand owners to ensure market compliant products through bespoke quality assurance and control programs.

Audits for Toys Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Pre-Production Inspection(PPI)

The first stage of the sporting goods inspection process takes place before the actual production begins or the first 10%-30% units produced. During Initial Production Inspection, inspectors work closely with manufacturers to review design specifications, verify material samples, and ensure that the factory has the capabilities to produce the sports equipment to the desired quality standards.

During Production Inspection (DUPRO)

Inspectors closely check the performance of sporting goods to identify any workmanship defects or deviations from the approved design. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard sports goods.

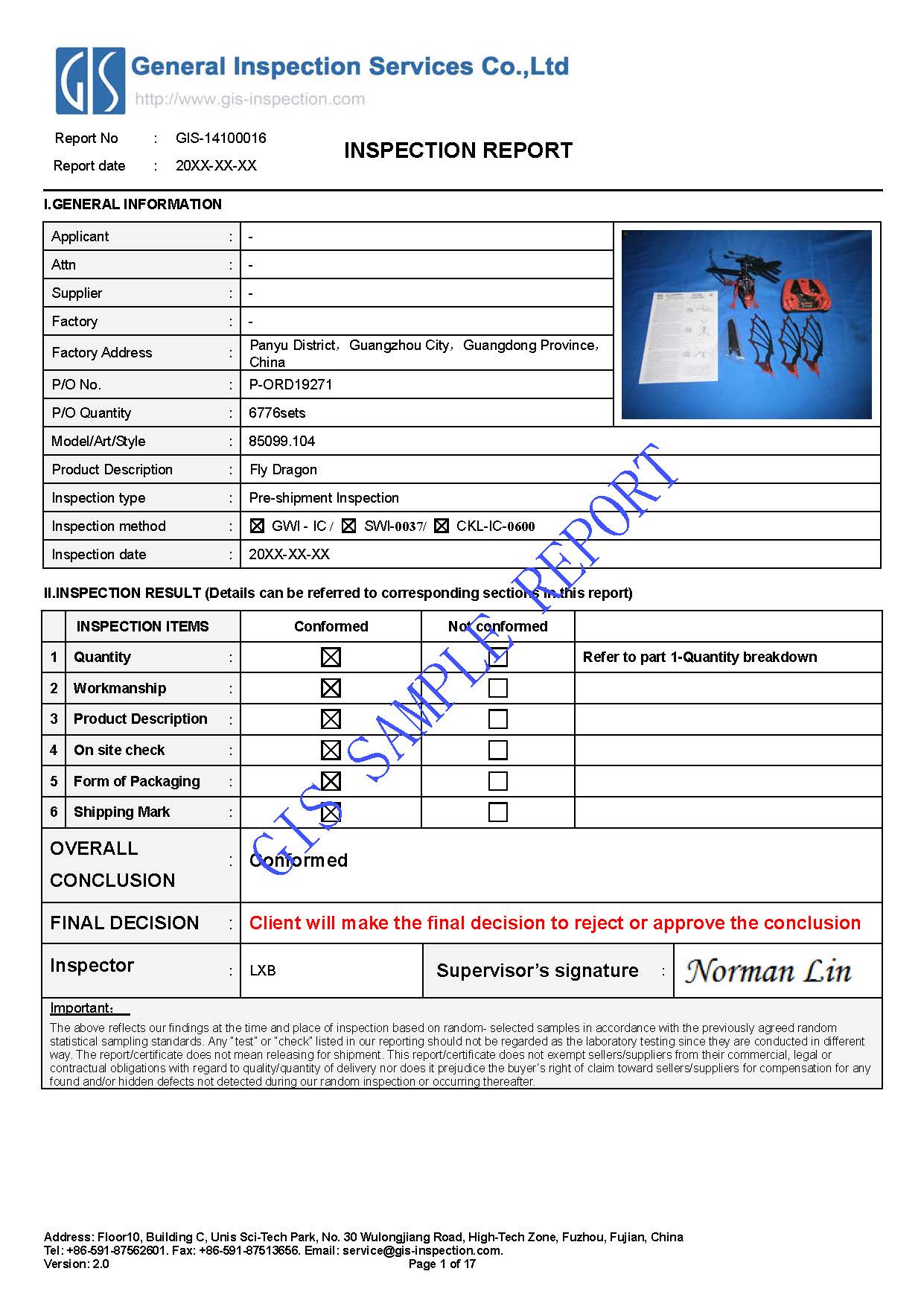

Pre-Shipment Inspection(PSI)

The pre-shipment inspection takes place when the merchandise is completed, packed and ready for shipment. Our inspectors pull a random sample of finished toys, based on internationally recognized statistical random sampling techniques.

Pre-shipment inspection covers the quality (product appearance, performance, function, color, size specifications, workmanship), quantity, packaging, labeling and shipping mark.

It helps to identify any defects or non-conformities in the batch, allowing for corrections before the products reach the customer, thereby safeguarding the buyer’s reputation and minimizing the risk of costly returns or complaints.

Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container.

Assessing manufacturing sites before initiating mass production and checking product quality prior to shipment are key parts of the quality control process, and vital to ensure that production is carried out according to the quality standards and expectations of destination markets.

Toys Pre-shipment Inspection Checklist

At GIS, we specialize in providing third-party inspection services for doll, plush toys, toy cars, puzzles, educational toys, and more at every stage: from supplier evaluation, audit to the quality control, final delivery of shipments during the process and supplier management.

Our dedicated team of inspectors follows a rigorous, on-site inspection protocol tailored to meet specific requirements and toy products’ categories. No matter your products are plush toys, wooden toys or electronic toys, the quality inspection protocols can be designed to best fit your expectations.

At GIS Inspection, our pre-shipment inspection checklist covers the following criteria:

- Quantity Verification

- Workmanship Inspection

- Product Description Verification

- Onsite-Test

- Packaging Inspection

1. Quantity Verification

The first step in pre-shipment inspection is the verification of the quantity. By comparing booking and actual quantities, GIS inspectors check products and shipping cartons to verify that total quantity matches the order confirm the total quantity matches the quantity indicated in the purchase order (PO).

2. Workmanship Inspection

If no specific requirement from applicant, the inspector will visually inspect the exterior and interior parts of the toys using inspection sampling plan, General Inspection Level II, AQL 2.5. 4.0.

Our inspector will check for the following aspects, including: scratches, cracks, dents, paint smudges, glue marks, misaligned parts, loose screws, gaps.

Learn more about AQL Sampling: https://www.gis-inspection.com/post/how-to-use-aql-for-quality-control-inspection

3. Product Description, Style and Color Verification

In this section, we verify if the style and construction of the toys match the approval sample and the client’s technical file.

- Verifying if the product matches the same style and materials as the approval sample.

- Inspecting if the same materials as the sample have been used which prevents discrepancies in quality, feel, and overall appearance.

- Checking if the actual products match the client’s technical file. It ensures that the final product adheres to the specific design, quality, and material requirements set by the client.

4. On-site Test for Toys

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards.

The essential inspection checklists for pre-shipment inspections to manage toys quality:

Carton size and weight check

- Carton assortment and quantity check

- Product size check

- Product weight check

- Barcode check

- Carton drop test

- Drop test

- Full Assembly Test

- Smell test

- Fastener Reliability Test

- Color Fastness Check

- Coating adhesive Tape Test

- Color shade check

- Tension test

- Stuffing material check

- Metal detection check

Check an inspection checklist template: https://www.gis-inspection.com/resource/sample-report

GIS Professional Inspection Services for Toys

GIS Inspection(General Inspection Service) is a leading third-party quality inspection agency in China. We are committed to helping you deliver toys that are safe, functional, and of the highest quality.

We offer Pre-Production Inspection(PPI), During Production Inspection (DUPRO) or Full Inspection services, and before delivery inspection to assess home goods and decoration items Pre-shipment Inspection(PPI).

Our dedicated technical professionals actively participate in the quality assurance industry and have an in-depth understanding of the standards and regulations of toys businesses.

Contact us for a chat about toys inspection now and see how we can support you with monitoring the quality of your toys industry!