When sourcing products from China and Asia, partnering with an experienced and reliable quality control inspection company is the key to fortify your supply chain and mitigate risk. Protect your brand with professional on-site inspections.

In this guide, we break down inspection range from three critical perspectives buyers care about most: geographic coverage and speed, product expertise, and inspection standards & procedures—so you know exactly what to expect before booking an inspection.

Local Expertise Strategic Inspection Hubs Across China and Asia

At GIS, we have strategically positioned our QC network to align with China’s key manufacturing hubs, ensuring we meet the rigorous supply chain security requirements of our global clients.

GIS Inspection operates through strategic hubs across major production regions, including:

- South China: Guangzhou, Shenzhen, Zhuhai, Shantou, Foshan, Jiangmen, Zhaoqing, Huizhou, Meizhou, Yangjiang, Qingyuan, Dongguan, Zhongshan, Chaozhou

- East China:

- Jiangsu: Nanjing, Wuxi, Xuzhou, Changzhou, Suzhou, Nantong, Lianyungang, Yancheng, Taizhou, Suqian

- Zhejiang: Hangzhou, Ningbo, Wenzhou, Jiaxing, Huzhou, Shaoxing, Jinhua, Quzhou , Taizhou, Lishui

- Anhui: Hefei, Wuhu, Bengbu, Tongling, Anqing, Huangshan, Chuzhou, Xuancheng

- Fujian: Fuzhou, Xiamen, Putian, Sanming, Quanzhou, Zhangzhou, Nanping, Longyan, Ningde

- Shandong: Jinan, Qingdao, Zibo, Yantai, Weifang, Liaocheng

- North China: Beijing, Hebei

- Central China: Henan

- Extended Coverage: Southeast Asia manufacturing regions

This localized QC network allows inspections to be conducted quickly, consistently, and cost-effectively.

Remote Areas & Travel Logistics: Transparent Inspection Range

Factories located outside core industrial zones are still within inspection range—but logistics matter.

For remote or less accessible locations:

- Travel distance is assessed in advance

- Any additional travel or accommodation fees are clearly quoted

- No hidden or last-minute charges

This transparency allows buyers to budget accurately and avoid inspection delays.

Industry Expertise: A Range That Matches Your Product DNA

From consumer goods and textiles to electronics, toys, furniture, and pet products, GIS Inspection supports diverse industries with reliable quality control and compliance solutions.

1. Electronics and Electrical Quality Control

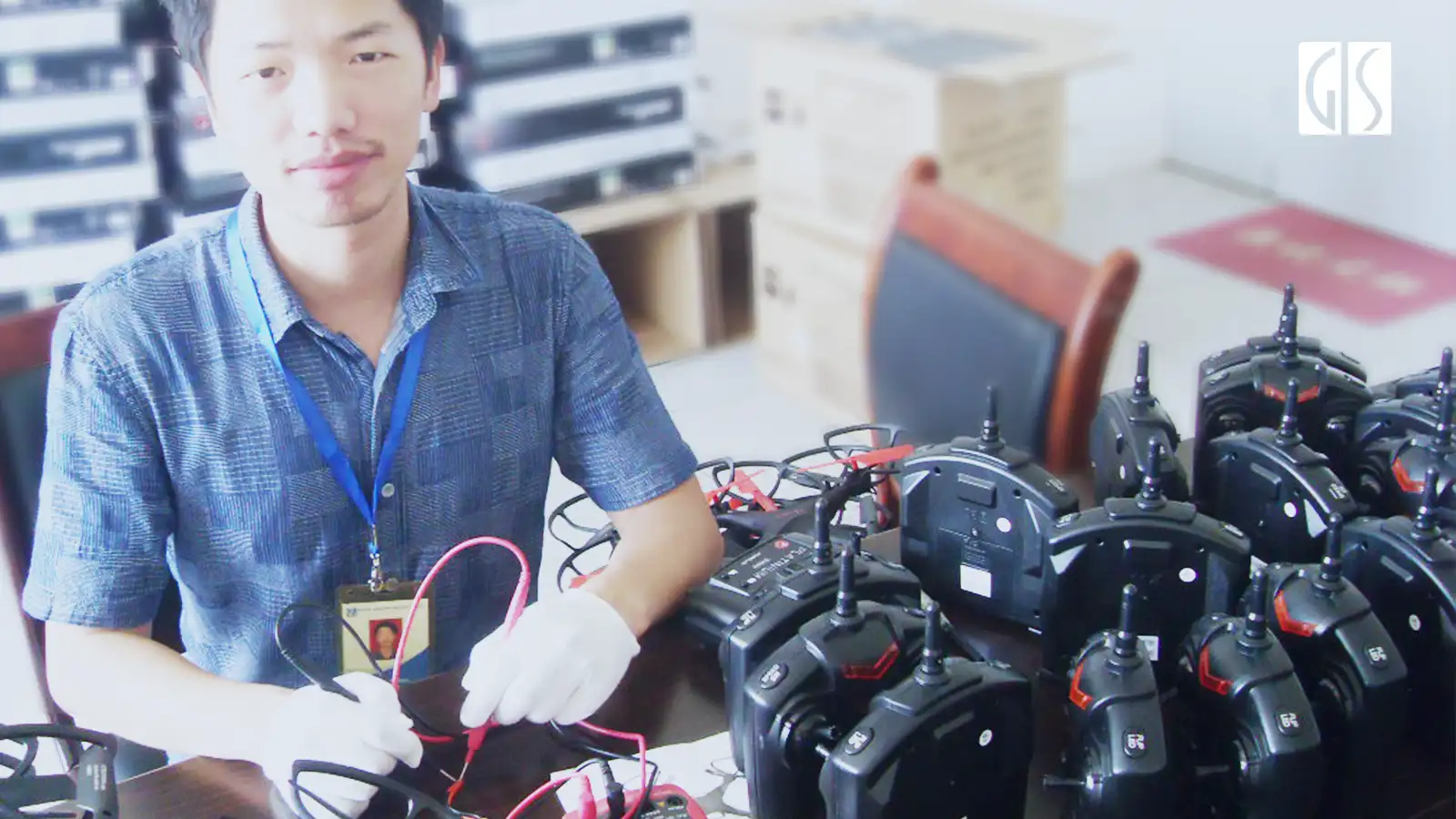

GIS inspector performing on-site Safety Test for client to guarantee reliable and certified product standards.

By combining advanced technology with decades of on-the-ground experience in electronics industry, GIS Inspection delivers comprehensive QC solutions in 60+ major cities throughout China and Southeast Asia.

Our deep understanding of international standards and customer expectations enables us to resolve a wide range of quality control challenges, support compliance with environmental and global market requirements, and strengthen buyer confidence at every stage of the supply chain.

GIS provides QC services across a wide range of electronic product categories, such as:

- Household electrical and electronic appliances

- Lighting and illumination products

- Audio/video and communication devices

- Computer and accessory hardware

- Electrical components and accessories

- Power tools and small electronics

These inspections typically check functional performance, safety attributes, dimensional accuracy, visual quality, electrical safety tests, and compliance with buyer‑specified requirements and relevant regulatory standards.

2. Textile and Garment Quality Control

Our expertise in Textiles & Apparel spans the entire production cycle, from raw material sourcing to final garment construction. We ensure every piece meets your brand's rigorous quality benchmarks:

- Appearance Inspection: The fabric is free from obvious defects, stains, and color shading issues.

- Sewing Workmanship Inspection: Stitching at all garment parts complies with specified workmanship standards and requirements.

- Measurement Check: Measurements are taken in accordance with the contract or applicable standards, including garment length, chest, sleeve length, shoulder width, and hem. For trousers, measurements include length, waist, and hip circumference.

- Accessories Inspection: Inspection of trims and accessories such as sewing thread color consistency, button size uniformity, and the condition and functionality of zippers.

2. Consumer Goods Quality Control

GIS Inspection helps manufacturers ensure that their products meet standards for safety, quality, and reliability.

- Checks raw materials, components, and finished goods.

- Reduces product defects and ensures market compliance.

- Evaluate the control of manufacturing process, especially for key processes or specific processes.

3. Industrial and Machinery Product Inspection in China

GIS Inspection helps industrial buyers ensure that heavy equipment and components meet technical specifications before shipment.

- Industrial Components: Castings, forgings, and machined parts.

- Machinery: Production line equipment and specialized industrial tools.

GIS Inspection ensures safety, compliance, and quality in industrial and machinery storage and transportation.

4. Food and Agriculture Quality Assurance in China

Managing the supply chain for fresh fruits, vegetables, and grains requires speed and precision to prevent spoilage.

- Quality Grading: Assessing size, color, ripeness, and weight according to international standards (e.g., USDA or EU grades).

- Defect Detection: Checking for bruising, mold, insect damage, or physiological disorders.

- Commodity Inspection: Verification of bulk shipments of rice, grains, sugar, and nuts, including moisture content testing and impurity analysis.

5. E-commerce & Amazon FBA Products QC Check in China

In the fast-paced world of digital retail, E-commerce and Amazon FBA (Fulfillment by Amazon) sellers face unique challenges. Product quality is directly tied to customer reviews, and high return rates can lead to account suspension.

- Amazon FBA Compliance & Preparation: Amazon has strict requirements for how goods enter their fulfillment centers. Failure to comply leads to "unfulfillable" inventory and extra fees

- Quality Control Tailored for Online Reviews: In E-commerce, a 3-star review can kill a product's momentum. We focus on visual perfection, functionality tests that matter to online shoppers.

Quality Inspection Range: What Is Actually Checked?

A standard GIS Inspection protocol includes five essential pillars:

1. Quantity Verification

Before beginning quality checks, the inspector will count the shipping cartons to verify that the correct number of products will be sent to the correct destination.

2. Workmanship & Visual Evaluation

The overall workmanship of the finished products is thoroughly examined to identify any visible defects. These defects are classified by severity based on predetermined acceptable tolerance levels, which are usually agreed upon between the supplier and manufacturer.

3. Product Specifications Checks

Inspectors verify product dimensions, weight, colors, style, construction, artwork, labels, and any other specific details against the provided samples and specifications. You can define these checks with a standard pre-shipment inspection checklist, or customize these checks by creating your own checklist.

4. On-site Functional Testing

At GIS, we offer tailored functional and safety testing solutions that align with both client specifications and the unique attributes of each product. These can include detailed checks related to specific areas of quality related to a specific product.

It should be pointed out that only certain aspects of safety can be tested in a PSI. In many cases, safety tests will need to be carried out in a laboratory.

5. Packaging & Labeling Compliance

Ensuring packaging methods, carton strength, labels, shipping marks, and manuals meet requirements.

6. Loading Supervision (When Applicable)

Monitoring container condition, loading methods, quantity accuracy, and cargo protection.

Expanding the Inspection Range

In certain cases, buyers may expand the inspection range to include:

- Stricter AQL levels

- 100% full inspection

- Extended functional testing

- Enhanced documentation or photo/video evidence

This is especially recommended for high-value, fragile, or regulated products.

Conclusion: Strategic Oversight for Global Peace of Mind

Not sure where to start your quality control process in China and Asia? At GIS Inspection, we offer thousands off-the-shelf quality control checklists, which can be fully customized to match your product inspection needs perfectly.

Ready to Secure Your Supply Chain?

Our product inspectors are dispatched to your supplier’s factory anywhere in the world within 48 hours. Contact us today to discuss a quality control program that will be a perfect fit for your business.