ASTM F2413-24-protective footwear standard provides guidelines on the performance of footwear to deliver protection against hazards that one might experience in the workplace.

"According to the Bureau of Labor Statistics, each year there are more than 53,000 foot injuries in U.S. workplaces that cause employees to miss work. Some result in permanent disability.

A crucial element of personal protective equipment (PPE) is safety footwear, which provides essential protection against potential foot injuries in hazardous work environments. With stringent regulations in place, manufacturers must comply with industry standards to ensure the quality and performance of their safety footwear.

What is ASTM F2413-24?

ASTM International sets standards for a wide range of products, including safety footwear. There are two ASTM International documents that govern safety footwear: ASTM F2413 and ASTM F2412.

ASTM F2413 – 24: Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear covers the minimum design, performance, testing, and classification requirements, and prescribes fit, function, and performance criteria for footwear designed to be worn to provide protection against a variety of workplace hazards that can potentially result in injury.

The standard encompasses an array of safety features, including impact resistance, compression resistance, metatarsal protection, puncture resistance, electric hazard protection, slip resistance, and sole durability. Meticulous testing is conducted on these features to ensure that safety footwear adequately protects the feet of workers who may be exposed to potential hazards in the workplace.

ASTM-F2413-24 is an updated version of the previous standard ASTM-F2413-18, and it sets higher requirements for footwear quality control. It is widely recognized and accepted by regulatory agencies, employers, and safety professionals as a benchmark for evaluating the quality and safety of safety footwear.

Manufacturers, distributors, and end-users of safety footwear are encouraged to comply with ASTM-F2413-24 to ensure that their products or the products they use meet the stringent safety requirements for workplace footwear.

Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear

ASTM F2413-24 provides minimum guidelines for the performance of footwear to provide protection against numerous workplace dangers that may result in injury. The ASTM-F2413 standard classifies safety toe caps into six main types:

1. Impact (l) and Compression (C) Resistant

1. Impact (l) and Compression (C) Resistant

Footwear shall meet the requirements of impact resistance and compression resistance. Any specimen that does not meet the minimum impact or compression performance resistance requirement constitutes a non-compliance for the product category.

Footwear shall be constructed and manufactured so that a protective toe cap is an integral and permanent part of the footwear. The toecaps shall be free from corrosion, sharp edges, burrs and defects that may affect safety performance. Each protective toe cap shall bear the manufacturer's name or trademark or logo. Cap number or identification, and toe capsize and R (right) or L (left) shall be permanently stamped or marked in a conspicuous location. Protective metallic toe caps shall have an open bottom. If a flange is present on a metallic toe cap, the width of the flange, when measured from the inside edge, shall be no greater than 10 mm (0.394 in.).

2. Metatarsal Protective (Mt)

Metatarsal (Mt) footwear reduces the chance of injury to the metatarsal bones on the top of the foot. The protection must be an integral and permanent part of the footwear and is measured after exposure to a 75 pound force. The required height clearance for men’s footwear is one inch and for women’s footwear it is 0.937 inches after exposure.

3. Conductive Protective (Cd)

Conductive (Cd) footwear is intended to provide protection for the wearer against hazards that may result from static electricity buildup and to help reduce the possibility of ignition of explosives or volatile chemicals.

Conductive protective Footwear shall be constructed and manufactured to provide protection through conductance with a maximum 500 000 resistance for the wearer against hazards that may result from static electricity buildup and to reduce the possibility of ignition of explosives such as munitions manufacturer.

Footwear shall dissipate static electricity from the body to reduce the possibility of ignition of volatile compounds.

Footwear shall be of a construction that facilitates as table electrically conductive path. All external components shall be made of non-metallic materials.

4. Electric Hazard Resistant (EH)

Electrical hazard (EH) footwear is manufactured with non-conductive, electrical-shock-resistant soles and heels.

Electric hazard footwear shall be constructed and manufactured so that the footwear outsole provides a supplemental form of protection to the wearer from hazardous step potential(the difference in electrical potential between the feet)while standing on the ground.

The outsole is intended to provide a secondary source of electric-shock-resistance protection to the wearer against the hazards from an incidental contact with live electrical circuits or electrically energized conductors, parts or apparatus. It must be capable of withstanding the application of 18,000 volts at 60 hertz for one minute with no current flow or leakage current in excess of one milliampere under dry conditions.

5. Static Dissipative (SD)

Static dissipative (SD) footwear is constructed and manufactured to provide protection through conduction and resistance to the wearer against hazards which may exist due to excessively low footwear resistance in a work environment, as well as maintain a sufficiently high level of resistance to reduce the possibility of electrical shock in work areas where SD footwear is worn such as electrical assembly.

Three different levels of electrical resistance are designated: SD 100, SD 35, and SD 10, based upon the following parameters:

- SD 100 — a lower limit of electrical resistance of 106ohms (1 megohm) and an upper limit of electrical resistance of 108ohms (100 megohms).

- SD 35 — a lower limit of 106ohms and an upper limit of 3.5 x 107ohms (35 megohms).

- SD 10 — a lower limit of electrical resistance of 106ohms and an upper limit of 1.0 x 107ohms (10 megohms).

6. Puncture Resistant (PR)

Puncture-resistant (PR) footwear is constructed, and manufactured so that a puncture resistant device is positioned between the foot and outsole or used as the insole and is made an integral and permanent part of the footwear during the manufacturing process.

Each puncture resistant protective device shall bear the manufacturer's name or trademark or logo, and device number or identification and be permanently stamped or marked in a conspicuous location.

The puncture resistant components shall reduce the possibility of injury caused by sharp objects that can penetrate the bottom assembly of the footwear. Testing orientation of the puncture resistant device is per manufacturer recommendation.

The puncture resistant device shall cover the maxi-mum area of the foot bottom that is allowed by the construction of the footwear.

A positive test result is achieved if the footwear’s bottom can be subjected to a 270 pound force without visual signs of penetration. The device must also show no sign of corrosion after being exposed to a five percent salt solution for 24 hours.

Measure flex resistance to cracking using CAN/CSAZ195. Puncture resistant devices shall show no signs of de-lamination of layers or cracking after 1.5 million flexes.

7. Slip Resistant footwear (SR or SRO)

Each footwear specimen tested to the requirements o fSR shall have a COF of no less than 0.40 when tested in bothheel and forepart modes using wet and dry quarry tile.

Each footwear specimen tested to the requirements of SRO shall meet the requirements of SR and also have a COF of no less than 0,33 when tested in both heel and fore part modes using oily wet quarry tile.

ASTM Labels: Protective Footwear Buyer's Guide

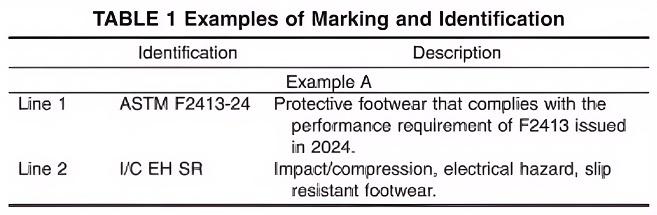

All footwear built to ASTM specifications must be labeled with appropriate safety feature marks on the inside or outside surface of the tongue, gusset, shaft or quarter lining in a 4-line format located inside a rectangle box.

Labeling and identification of protective footwear with protective toe cap is essential to ensure the wearer that footwear meets the required minimum performance of this specification.

The label can be either a stitched in, stamped, or pressure sensitized label or a combination of these methods. A specific four line format that identifies the type of footwear and the hazards for which it is designed to provide protection should be used, The identification shall be enclosed in a rectangular border and be placed on the inside or outside surface of either the tongue, gusset, shaft or quarter lining in one half pair.

Print size on labels shall be clearly visual to the eye and shall measure 3.175 mm (0.125 in.) or larger.

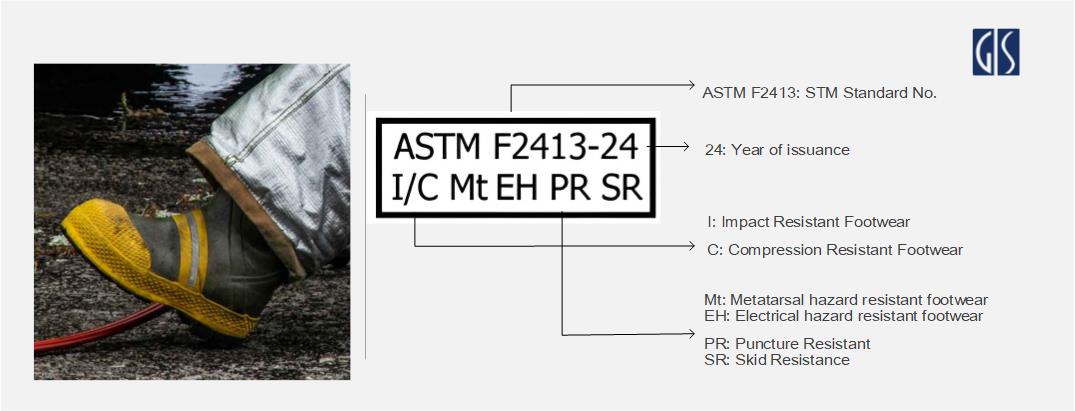

The following is an example of an ASTM F2413-24 marking that may be found on protective footwear:

ASTM F2413-24

I/C

Mt EH PR SR

Line #1: ASTM F2413-24

Line 1-Identifies that the footwear is protective footwear that complies to an ASTM standard with a specific year of issuance.

Line #2: I/C MT EH PR SR

Lines 2 and onward have been used to reference additional sections in this standard, Section reference shall be in numerical order.

- (I/C)-Identifies protection against impact and com-pression;

- (Mr)-Identifes footwear designed to be impact resistant to the top of the foot;

- (Cd)-Identifes protection against conductive hazards;

- (EH)-Identifies footwear constructed with andmanu factured to have electrical insulation properties; electrical hazard resistant;

- (SD 100)-Identifies footwear designed to reduce the accumulation of excess static electricity;

- (SD 35)-Identifes footwear designed to reduce the accumulation of excess static electricity;

- (SD 10)-Identifes footwear designed to reduce the accumulation of excess static electricity;

- (PR)-Identifies footwear designed to be puncture resistant;

- (SR or SRO)-Identifes the footwear as meeting the slip resistant requirements.

Reporting of Results and Certificate of Conformance (COC)

1. With each new year date revision of SpecificationF2413, shoe manufactures/providers are required to re-certify existing styles within one year of the issuing date.

2. With the issuance of a new year date standard, certification of new product to any prior year date standard is not allowed.

3. A test report shall be issued by a third Party laboratory for the safety hazard(s) applicable to the footwear and puncture resistant devices tested. The test report shall include but not be limited to:

- Third Party laboratory name, contact information and authorization signature(s).

- Reference to ASTM Test Methods F2412 and to ASTM Specification F2413.

- Full description of the sample footwear or puncture resistant devices tested, or both, including any manufacturer's reference (Product Category, style, model, SKU etc.), size and gender.

- Performance requirements and safety hazard(s) tested.

- For each safety hazard(s) tested, report the results for each individual specimen as well as the average of the specimens, and state if the footwear or puncture resistant device, or both, has passed or failed.7.3.1.6 The atmosphere (temperature and humidity) under which the footwear or puncture resistant devices, or both, were conditioned and tested.

4. Any modification of the test methods.

A Certificate of Conformance (COC) shall be issued by a 3rd Party laboratory for the safety hazard(s) applicable to the footwear or puncture resistant devices, or both, tested.

The Certificate of Conformance (COC) shall include but not be limited to:

- Third party laboratory name, contact information and authorization signature(s).

- Name of company the Certificate of Compliance (COC) is issued to.

- All manufacturer's references (product category style, model, SKU, etc.).

- Certification issue date.

- Report number and issue date associated with this Certificate of Compliance (COC).

- Statement that the manufacturer's reference (product category style, model, SKU,etc) meets the performance requirements of ASTM Specification F2413-24 as tested in accordance with ASTM Test Methods F2412-18 and list the safety hazard(s) tested.

- Certificates of Conformance(COC)may be amended to add new styles, models, SKU's between standard revisions if there are no changes requiring retesting.

GIS Inspection can Help

GIS Inspection is the top trusted quality control inspection company in China and Asia. Every year, thousands of work place injuries occur that could have been prevented with the right gear.

Safety work shoes are tested according to ASTM 2413-24 standards for impact and compression safety-toe resistance, metatarsal protection, conductivity resistance, electrical shock resistance, static dissipative properties, puncture resistance, and slip resistant.

GIS Inspection is a leading 3rd-party quality assurance inspection agency in China. We are committed to helping you deliver safety footwear that are safe, functional, and of the highest quality.

We offer Pre-Production Inspection(PPI), During Production Inspection (DUPRO) or Full Inspection services, and before delivery inspection to assess home goods and decoration items Pre-shipment Inspection(PPI).

Our dedicated technical professionals actively participate in the quality assurance industry and have an in-depth understanding of the standards and regulations of shoes businesses.

Contact us for a chat about shoes inspection now and see how we can support you with monitoring the quality of your footwear industry!

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.