Home appliances | Lighting | Electrical Accessories | Computer Device | Power tools | Electronic equipment

Electrical accessories include a wide range of components such as switches, sockets, plug, circuit breakers, cable lugs, terminals, conduits, and more.

If you are importing electrical accessories, it is always crucial to implement robust quality control management at the factories to minimize risks associated with safety failures and quality defects. Third-party on-site quality inspection at factories is an essential part of quality control management.

GIS Inspection (General Inspection Service) is a global provider in electrical accessories quality control inspection services. To ensure your electrical accessories products are safe and compliant, book a third-party inspection service today.

Content

Electrical Accessories Quality Control Inspection

GIS Inspection has served the needs of the electrical accessories industry through a wide range of quality assurance solutions for 20 years.

GIS Inspection continually adapts to changes in the electrical accessories industry by enhancing our existing quality solutions, expertise and methods. GIS Inspection aims to guarantee the quality of electrical accessories and create a trustful environment between buyers and manufacturers.

GIS Inspection’s range of quality assurance and quality control services for electrical accessories allows customers to solve non-conformities at each step of the production process and to ensure a high level of system compliance and stability.

Whether our clients are looking to optimize their quality management systems, improve the quality performance of their factories or suppliers, or control product quality, it is essential to demonstrate a high level of expertise and reliability.

The Importance of Electrical Accessories Inspection

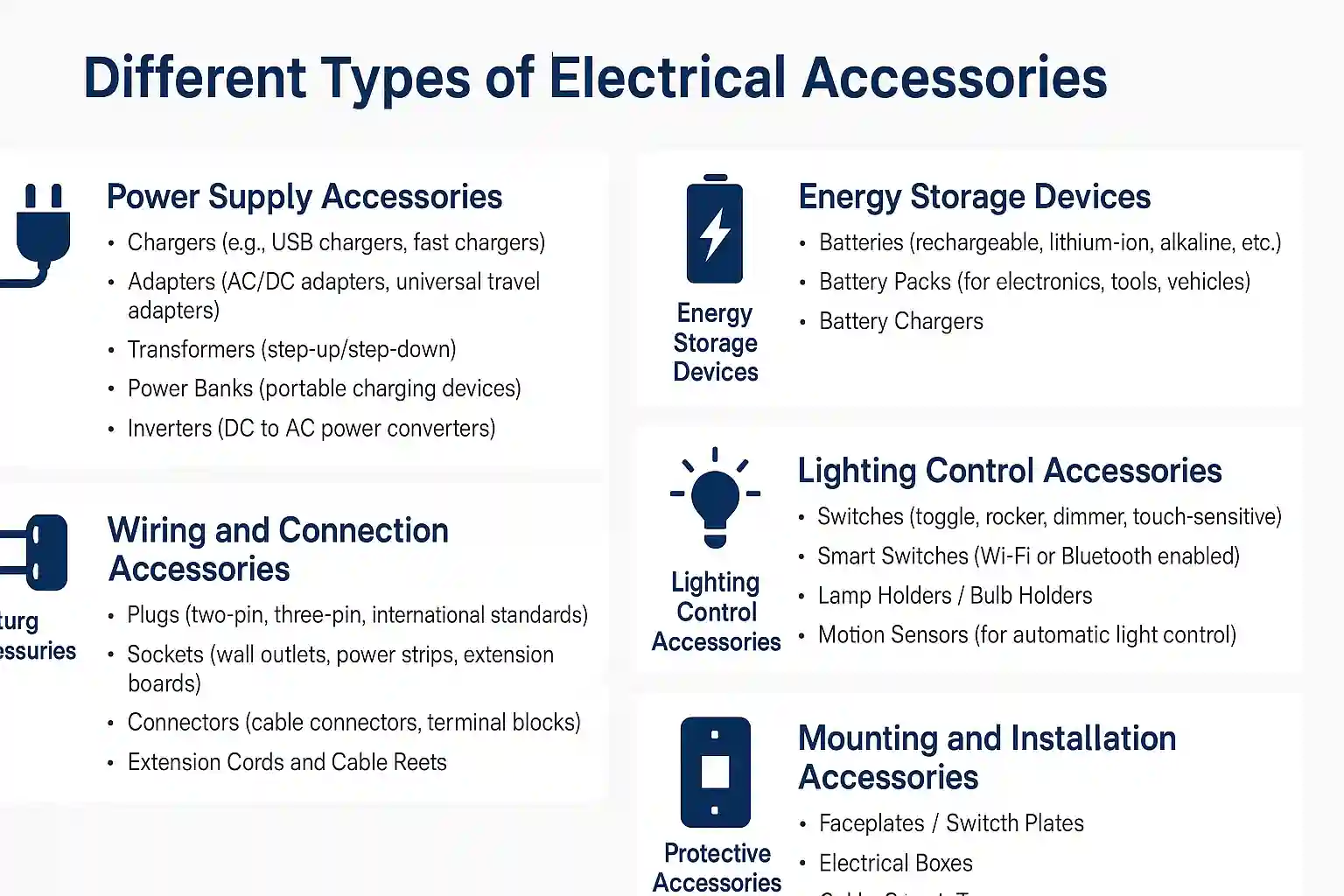

Electrical accessories—including chargers, batteries, adapters, transformers, plugs, sockets, switches, and lamp holders—play a critical role in ensuring the safety, functionality, and reliability of electrical systems in both residential and commercial environments.

1. Ensuring Electrical Safety

1. Ensuring Electrical Safety

Electrical accessories that are poorly manufactured or defective can pose serious risks, such as short circuits, electric shocks, overheating, or even fire hazards. Quality inspection helps identify faulty insulation or exposed wiring and non-compliance with safety markings or certifications.

2. Compliance with Regulatory Requirements

Electrical accessories are subject to a variety of regulations depending on the destination market. Inspections help verify proper labeling and compliance marks (CE, CCC, FCC, etc.), and use of RoHS-compliant materials (no lead, mercury, cadmium, etc.). Early identification of non-compliant items avoids penalties, recalls, and shipment rejections.

3. Functional and Durability Testing

Beyond safety, inspections ensure the accessories function correctly under expected conditions. By verifying these parameters, manufacturers and buyers can ensure the product performs as advertised throughout its lifecycle.

4. Brand Reputation and Customer Trust

In the competitive electronics and hardware market, a single faulty accessory can lead to customer dissatisfaction, negative reviews, and brand damage. Quality inspection builds a foundation for consistent product quality and enhanced end-user safety and trust

The Different Types of Electrical Accessories We Inspect

We can inspect a large variety of electrical accessories such as:

- Charges

- Adapters

- Transformers

- Plugs

- Sockets

- Connectors

- Extension Cords and Cable Reels

- Switches

- Lamp Holders

- Remote controls

- smart home systems.

Types of Third-party Electrical Accessories Quality Control

Audits for the Electrical Accessories Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Pre-Production Inspection(PPI)

GIS inspectors onsite will evaluate the first 10%-30% units produced to ensure compliance with necessary criteria, brand specifications, quality requirements which can firmly establish whether the manufacturer will be able to deliver on the promise to produce a quality product using the correct materials and manufacturing process, and orders shipping on time.

During Production Inspection (DUPRO)

The electrical accessories will be examined for their appearance, construction, and function to ensure that quality requirements and specifications are met. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard electrical accessorie products.

Pre-Shipment Inspection(PSI)

We will select a random sample of finished electrical accessories before shipment to ensure all items conform to the established quality criteria and functional requirements. Functional tests on electrical accessories are performed to ensure usability, efficiency, and safety.

Inspectors supervise the packaging process to verify that the electrical accessories are adequately protected for transportation. They also ensure proper loading onto shipping containers to prevent damage during transit.

Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container.

Essential Electrical Accessories Inspection Checklist during an onsite Inspection

A comprehensive pre-shipment quality inspection checklist for electrical accessories is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

1. Quantity check

GIS inspectors count products and shipping cartons to verify that the correct quantity of an order has been finished which including PO quantity, shipment quantity, packed quantity, unpacked quantity, and unfinished quantity.

2. Workmanship Inspection

The GIS inspector will select a sample size according to the AQL standard, and conduct a visual check for any damages and flaws in workmanship and classify them as major, minor, or critical defects. The electrical accessories random inspection AQL standard is normally 1.5 for major defects, 4.0 for minor defects.

Read more: How to Use AQL for Quality Control Inspection?

3. Product description, style and color check

GIS Inspection will verify that the products conform to the specifications against PO, photos, and sample.

4. On-site test

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards.

The essential tests performed by our inspectors during an onsite inspection of electrical accessories:

- Hi voltage check

- Earth resistance check

- Basic function check

- Assembly check

- Transportation drop test

- Power consumption check

- Product measurement Barcode readability check

- Power cord length check

- Internal check for workmanship

- Speed check (no load)

- Vibration Test

- Noise Emission Test

5. Packaging Check

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

6. Shipping mark check

Shipping mark check covers key quality aspects that help ensure products are safe, functional, and compliant with industry standards before reaching the market.

International IEC Electrical Standards for Electrical Accessories

IEC 60884 and IEC 60309 – Standards for Plugs and Sockets

IEC 60884 Plugs and socket-outlets for household and similar purposes

IEC 60884 specifies common requirements and rules applicable to plugs and fixed or portable socket-outlets for AC only, with or without earthing contact, with a rated voltage greater than 50 V but not exceeding 440 V and a rated current not exceeding 32 A, intended for household and similar purposes, either indoors or outdoors.

IEC 60320 on Appliance Couplers

The IEC 60320 set of international standards specifies safety and testing requirements for non-locking appliances as well as interconnection couplers connecting power supply cords to electrical appliances. Appliance couplers enable manufacturers serving the international market to produce a single electrical device for most of their diverse markets, having only to adapt or change cords for particular markets of exception.

IEC 60669 – Switches for Fixed Electrical Installations

IEC 60669 is a standard that specifies requirements for manually operated switches used in fixed electrical installations, whether indoors or outdoors. The standard includes mechanical and electrical endurance testing, resistance to heat and fire, insulation properties, and proper marking requirements.

IEC 60884-2-5 – Particular Requirements for Adaptors

IEC 60884-2-5 is part of the IEC 60884 series that deals with plugs and socket-outlets for household and similar purposes. It addresses the mechanical strength, temperature rise, insulation resistance, and constructional features specific to adaptors.

GIS Inspection for you Electrical Accessories Quality Control

GIS Inspection(General Inspection Service) is an international third-party quality control inspection company in China. GIS provides provide comprehensive safety and quality assurance services to help you ensure compliance with legislation enforced in multiple global markets. We have set up an inspection network covering China, Vietnam, Malaysia, India.

We conduct all inspections for electrical accessories as mandated by relevant laws and regulations. Thanks to our many years of experience and our comprehensive know-how, we are the right partner to stand at your side.

GIS only employs full-time inspectors. Our highly trained and experienced electrical & electronics inspectors are product experts who receive regular training in their field of specialization.

GIS product inspection services ensure that your products match your desired specifications. Contact our electrical accessories quality assurance experts to customize your inspection requirements.