Each type of outdoor furniture, whether it's chairs, tables for contract use, domestic use or leisure use, is subject to its unique set of regulations. At GIS Inspection, our rigorous outdoor furniture quality inspections service ensuring the product's high quality and furniture product safety that adds value to your brand.

In this artile, we will explore the outdoor furniture standard in EU and US, the PSI inspection for garden furniture, and the inspection checklists.

Contents:

What is Outdoor Furniture Quality Inspection?

Outdoor Furniture Standards and Regulations

What is an Outdoor Furniture Pre-shipment Inspection?

Comprehensive Outdoor Furniture Inspection Checklist

What is Outdoor Furniture Quality Inspection?

Outdoor furniture Quality Inspection is a comprehensive process of checking outdoor furniture including seating, tables, dining furniture, lounge furniture, sun loungers, daybeds, outdoor benches for fabrics, durability, functionality, and safety to ensure it meets specified standards and customer requirements.

Outdoor furniture inspection plays a pivotal role in the manufacturing and distribution process for patio furniture companies and buyers. It is crucial to ensure that the products meet quality standards, safety regulations, and customer expectations.

Check out outdoor furniture inspection report sample!

Outdoor Furniture Standards and Regulations

Outdoor garden chairs and tables need to meet different standards than their in-home counterparts. That's because outdoor furniture items need to be able to withstand the outdoor elements while maintaining their visual and structural integrity.

European Outdoor Furniture Standards (EN)

The outdoor furniture, intended as seats and tables, is currently governed by the following three standards:

EN 581-1 2017 Outdoor furniture

Seating and tables for camping, domestic and contract use – Part 1: General safety requirements

EN 581-2:2015 Outdoor furniture

Seating and tables for camping, domestic and contract use - Part 2: Mechanical safety requirements and test methods for seating

EN 581-3:2017 Outdoor furniture

Seating and tables for camping, domestic and contract use - Part 3: Mechanical safety requirements for tables

EN 581-1 is the first part of the EN 581 series of standards that focuses specifies the general safety requirements for outdoor seating and tables for camping, domestic, and contract for use by adults, without regard to materials, design/construction, or manufacturing processes.

EN 581-2 specifies minimum safety, strength, and durability requirements for all outdoor seating, and EN 581-3 does the same for all outdoor tables (for adults). Both parts apply regardless of the material or design/manufacturing process.

Read the details about EN 581-1 2017 Outdoor furniture Seating and Tables

Outdoor Furniture Standard in the US

The standards for outdoor furniture in the US are primarily a combination of voluntary industry standards and mandatory federal regulations that mainly focus on safety, especially for upholstered items and children's products.

Key standards and regulatory bodies

- ASTM F1561 Standard Performance Requirements for Plastic Chairs for Outdoor Use

- ASTM F1838 Standard Performance Requirements for Adult and Children’s Plastic Chairs for Outdoor Use

These standards establish performance requirements for specific types of outdoor plastic furniture (like chairs and chaises). Tests cover impact, static load capacity, and rear leg strength for both residential and commercial use.

Mandatory Federal Regulations (CPSC)

The Consumer Product Safety Commission (CPSC) enforces mandatory requirements that apply to all consumer products sold in the US, including outdoor furniture.

- Flammability: The CPSC enforces the federal flammability standard for upholstered furniture (including cushions on outdoor furniture), requiring compliance with the test method specified in California Technical Bulletin (TB) 117-2013.

- Lead Content: Federal limits are enforced on the concentration of lead in paint and other surface coatings on all consumer furniture.

- Mechanical Hazards: Manufacturers have a general duty to ensure products do not present a risk of injury. This includes avoiding hazards like shear and pinch points and ensuring stability to prevent tipping, especially for children's furniture.

- Children's Products: Outdoor children's furniture has stricter mandatory requirements and requires third-party testing and certification for compliance with specific standards (e.g., CPSC and certain ASTM standards like ASTM F1838 for child's plastic chairs).

What is an Outdoor Furniture Pre-shipment Inspection?

An outdoor furniture pre-shipment inspection is a quality control process conducted prior to shipment to confirm that the products such as outdoor table and seating meet specified industry standards and your exact customer requirements.

It involves checking the material quality, verifying color and pattern accuracy, confirming correct dimensions, examining workmanship and assembly, assessing structural stability and functionality, and reviewing labeling, packaging, and carton condition to ensure the products are ready for safe transportation and market compliance.

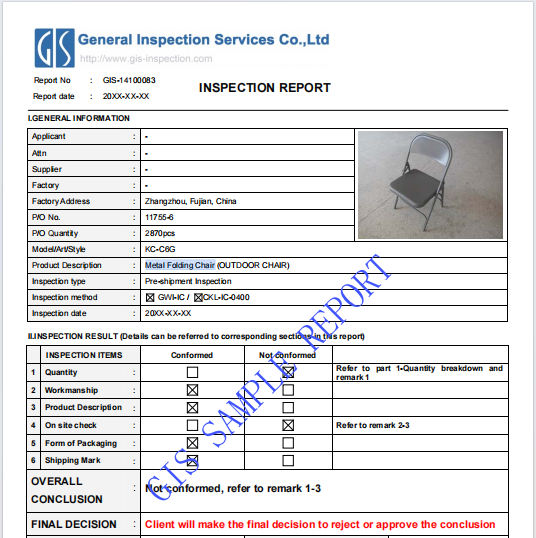

As an example, we will present you below in the article a real inspection report of a service we conducted for outdoor seatings

Sampling Plan and AQL for Outdoor Furniture Pre-Shipment Inspections

We verify mass production quality based on your Acceptable Quality Limits (AQL), identifying and classifying defects to offer an overview of your product’s quality.

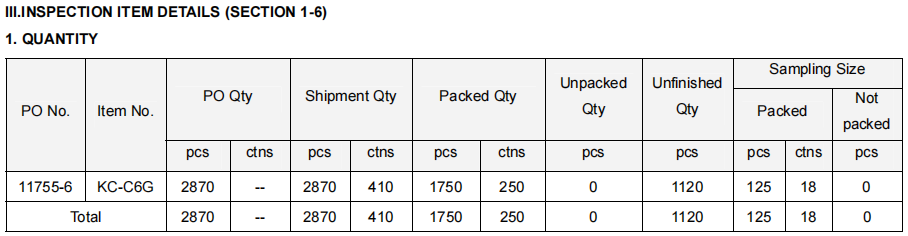

In our Metal Folding Chair (OUTDOOR CHAIR) pre-shipment inspection example, the total number of pieces produced is 2870. The first step is to determine the number of tables to inspect, which is where the sampling size comes into play. The sampling size isn’t just a random selection of units; it’s a carefully calculated number based on specific criteria, ensuring a representative and efficient inspection process.

- Workmanship Check: This involves assessing the overall quality and workmanship of the tents. For a batch size of 2870 pcs, a General Level II (GII) approach is recommended. In practical terms, this means inspecting 125 pcs.

- On site Check: Sometimes, certain aspects of the product require more focused attention. The on site check involves:

-

Basic function check: full sample

-

Transportation Drop Test: 1carton

-

Stability check at 15 degree: 3 sample

- Assembly check: 5 Samples

- Loading check: 3 Samples

- Impact check for Chair: 5 Samples

- Moisture content check: 5 Samples

- Coating adhesive check by 3M tape: 5 Samples

- 3M tape check for painting: 5 Samples

Key Elements of Outdoor Furniture PSI inspection

Material Quality Assessment

During garden and patio furniture inspection, the materials used in the manufacturing process are carefully examined to verify their quality and suitability for the intended use. This assessment includes:

- Wood and Wood-Based Materials: Inspecting the type of wood used, checking for knots, warping, and signs of damage.

- Upholstery and Fabrics: Assessing the fabric quality, stitching, and overall upholstery finish.

- Metal Components: Checking for rust, cracks, or sharp edges in metal parts of the outdoor furniture.

Structural Integrity Checks

The structural stability and integrity of the outdoor furniture are critical to its safety and performance. The inspection includes:

- Frame and Joint Stability: Ensuring that the frame is sturdy and joints are securely fastened.

- Load-Bearing Capacity: Verifying that the outdoor furniture can support the intended weight without failure.

- Fastener Strength: Checking the strength of screws, bolts, and other fasteners used in assembly.

Finishing and Surface Evaluation

The finishing and surface quality of the outdoor furniture contribute to its overall aesthetics and durability. Inspection covers:

- Surface Smoothness and Finish Consistency: Ensuring a smooth and uniform finish without rough spots or irregularities.

- Stain and Scratch Resistance: Testing the resistance of the surface to stains and scratches.

- Colorfastness and Fading: Verifying that the color of the outdoor furniture remains consistent and does not fade easily.

Safety Features Assessment

For garden furniture designed for specific purposes, such as cribs or highchairs, safety features are essential. The inspection includes:

- Safety Mechanisms: Checking the functionality of safety features, such as locks or latches. Edge and Corner Protection: Ensuring that sharp edges and corners are adequately covered or rounded.

Assembly and Packaging Verification

Inspectors assess how well the outdoor garden furniture is assembled and packaged for shipping to prevent damages during transportation. This involves:

- Assembly Quality: Verifying that the outdoor furniture is assembled correctly according to the provided instructions.

- Packaging Integrity: Ensuring that the packaging provides adequate protection during transit.

Compliance with Quality Standards

Throughout the inspection process, the outdoor furniture is checked against applicable quality standards, both national and international, to ensure that it meets the required criteria.

Functionality and Performance Testing

Inspectors may conduct functional tests to evaluate how well the outdoor furniture performs its intended functions. For example, testing the reclining mechanism in a recliner chair or the smooth movement of drawers in a dresser.

Workmanship and Appearance

The overall workmanship and appearance of the outdoor furniture are evaluated to ensure a high level of craftsmanship and attention to detail.

Schedule Your Outdoor Furniture Inspection Today!

By employing an independent quality control inspection agency in China like GIS Inspection, quality concerns will be identified and controlled at the very source.

Comprehensive Outdoor Furniture Inspection Checklist

At GIS Inspection, our outdoor tables and chairs pre-shipment inspection checklist covers the following criteria:

- Quantity Verification

- Product Workmanship Verification

- Product Style and Construction Inspection

- Functional and Performance Tests

- Measurement Data Check

- Package and Packaging Inspection

- Product Labelling and Markings Inspection

In the section below, we present the details of each criterion, including pictures, based on our example of outdoor chair inspection.

1. Quantity Verification

The first step in any pre-shipment inspection is the verification of the quantity. This evaluation checks if the actual quantity ready to be shipped to the client matches the quantity indicated in the purchase order (PO). The key aspects that need to be assessed during this stage include:

- The precise count of products manufactured, confirming they match the quantity specified in the PO.

- Verification of style or model numbers, ensuring every product aligns with the designated style.

- Verification of the color, ensuring they meet the precise specifications provided in the P.O.

For our outdoor chair inspection example, we have reported the quantity as per the following in our inspection report.

Outdoor chair-metal folding chair pre shipment inspection report-quantity check

2. Product Workmanship Verification

Visually inspecting the product’s physical conditions, appearance, and cleanliness.

Those visual defects are categorized by defect category in a table within the inspection report as follows:

Garden chair pre shipment Inspection Workmanship inspection

Here are examples of quality defects that we identified during the garden chair inspection:

outdoor chair pre shipment Inspection Workmanship inspection defects

3. Product Style and Construction Inspection

Our inspectors verify if the style and color of the outdoor furniture product match the approval sample and the client’s technical file.

- Verifying if the product matches the same style and materials as the approval sample.

- Inspecting if the same materials as the sample have been used which prevents discrepancies in quality, feel, and overall appearance.

- Checking if the actual products match the client’s technical file. It ensures that the final product adheres to the specific design, quality, and material requirements set by the client.

4. Functional and Performance Tests

- Assembly check (according to instruction manual)

- Loading check:

- For camping chair: 110 kgs on seat last for 1 hour

- For domestic chair: 160 kgs on seat last for 1 hour

- For table: camping: 50 kgs, domestic: 75kgs (force apply on center of table)

If the length is more 160cm, two forces were apply on longitudinal axis of the table top with a distance of 40cm on either side of the transversal axis.

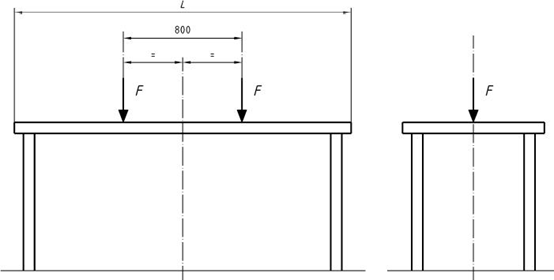

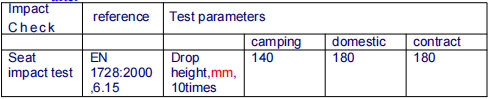

- Impact check for Chair

Procedure: Free drop 25kgs load from xx cm height for 10 times,

- To check if any deformation and breakage was found on chair.

- for child

Loading and impact check with half weight of adult, if the claimed max weight is heavier than half of adult ,we use claimed max weight for check.

- Moisture content check

- Coating adhesive check by 3M tape

- 3M tape check for painting

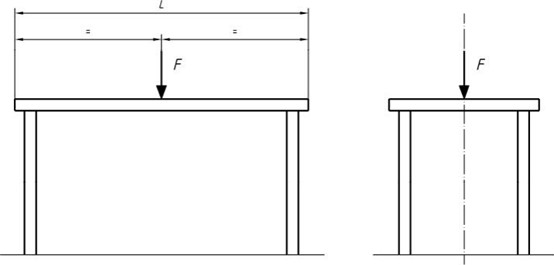

Outdoor table and chair test in Eu

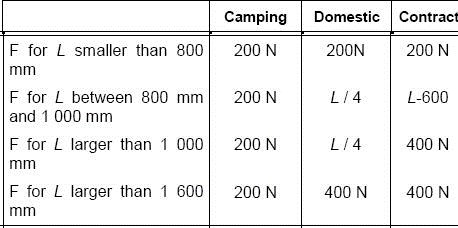

For table selling in Europe:

1. Stability (5 Samples)

-Measure the largest dimension of the table top(L)

-Use this dimension, determine the force F per table as below:

-Apply the the force F to the side where the load is most likely to cause overturning, as far away from the supports as possible, and at a point 50mm from the outer edge of the table top

-Table overturn

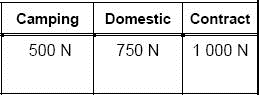

2.Static loading check (5 samples)

-Load the table with the weight as below:

-The application points is as below:

1) L<=1600mm, at the geometric center point of the table

2) L>1600mm, at 2 points positioned on the longitudinal axis of the

table top with 400mm on either side of the transversal axis

-Hold for one hour

-Collapse, damage and loose structure

For chair selling in Europe:

1. Drop 25kgs weight to seat (about center position) from xx cm height for 10 times, check if breakage, detach, deformation is found after check, the slight deformation that not affect the use and function is acceptable.

For articles with more than one seating position apply the rest to one end seat and an intermediate seating position.

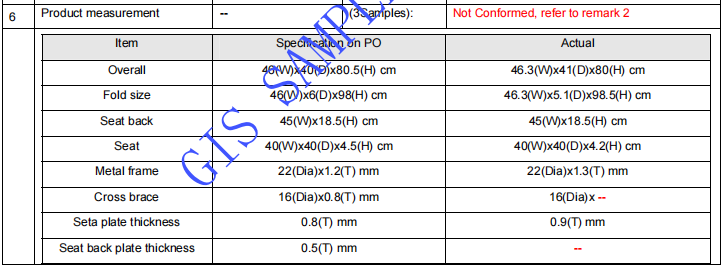

5. Measurement Data Inspection

During the inspection, precise measurements are a critical aspect to evaluate. This involves verifying several key dimensions including the item: overall, fold size, seat back,

seat, metal frame, cross brace, seta plate thickness, and seat back plate thickness to ensure consistency and adherence to design specifications (within tolerances or out of tolerances).

For this outdoor chair inspection, product weight and product size are measured to guarantee they align with the design specifications.

In the metal folding chair pre-shipment inspection report, the results of the measurement data check are presented in a table as follows:

metal folding chair pre shipment Inspection size measurement

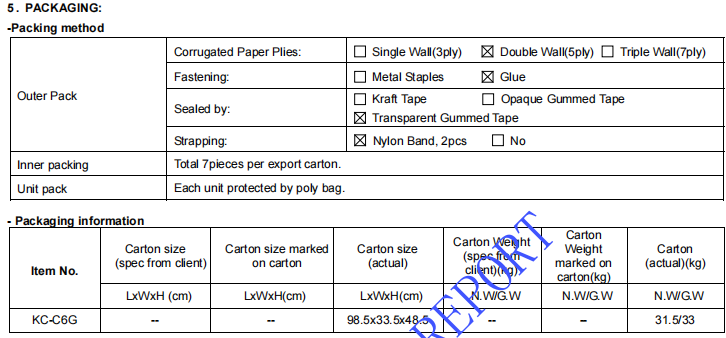

6. Package and Packaging Inspection

This stage is essential not only for upholding the brand’s image but also for ensuring that the packaging is robust and suitable for transit, minimizing the risk of damage. It includes:

- Packing method and conditions check to ensures the method of packing is appropriate for the product, protecting it from damage during transit and storage. It includes the carton dimensions, carton weight, sealing method (staples, adhesive, plastic band or metal band), and the carton quality.

- Shipping marks/labels check to verify the accuracy and visibility of shipping marks and labels aids in proper handling and routing during shipping.

- Retail package artwork check to ensures the packaging aligns with brand standards and marketing requirements, enhancing customer appeal.

7. Product Labelling and Markings Inspection

Label and marking test to verifying that the label & marking have the correct content.

GIS Inspection’s Outdoor Furniture Quality Control Services

GIS Inspection provides comprehensive pre-production, during production, and pre-shipment inspections, following the AQL standards, leaving no room for subpar products to slip through the cracks.

Our outdoor garden furniture Inspection report comes with digital evidence, enabling efficient identification, categorization of defects and recommendations. With GIS Inspection, you can expect timely and detailed inspection reports, allowing you to take prompt action if any issues arise.

GIS Inspection has a strong network of 300+ skilled inspectors located in 10 countries, catering to diverse clients and industries.

With over 20 years of quality assurance experience across China and Asia, General Inspection Services is ready to help your business build strong and meaningful supplier relationships. Whether you need a China pre shipment inspection, or a supplier audit. We’re the best third-party quality inspection agency in China.

Book an outdoor furniture inspection service today!

FAQs

Q1. GIS Outdoor Furniture Quality Inspection Categories

01. Outdoor furniture for Contract Use: This furniture is designed for public areas such as restaurants, hotels, public swimming pools, and tourist resorts. Due to high usage and public liability, these pieces require enhanced durability, strength, and structural integrity (high resistance to stress/pressure) compared to residential items.

02. Outdoor furniture for Domestic Use: Furniture intended for private settings, such as a home garden, balcony, or patio/deck.

03. Outdoor furniture for Camping Use: Lightweight and easily transported, this furniture is typically foldable, collapsible, or detachable. It is used for camping or travel, such as fishing chairs or beach chairs.

Q2: Outdoor Furniture Inspection Process

pre-production inspection: for outdoor furniture: The first stage of the furniture inspection process takes place before the actual production begins.

During production inspection: for outdoor furniture: Verifying the fundamental build quality and checking for issues while the goods are still on the assembly line or being finished.

Final Inspection for Furniture: The final inspection is conducted once the furniture production is completed and a batch of products is ready for shipment.

Loading Supervision: During Container Loading Inspection, inspectors oversee the packaging process to ensure that the furniture is adequately protected for transportation and loaded correctly onto shipping containers.

Q3: Outdoor Furniture Inspection Report Sample

Furniture inspection reports should be as detailed as possible and include:

- Inspection Information – clients name, suppliers’ information, product name, inspection date, inspector’s name, factory, quantity, location and the name of the staff member the product was reviewed by:

- Inspected articles –photos of the product.

- Inspection Standard – inspection type, default levels, specify defects and level the defect by critical, major or minor categories.

- Inspection Result – score the quantity, visual and workmanship, data measurement, packaging and shipping mark by ‘conform’, ‘not conform’ or ‘pending’.

- Remark Points –attach any defect pictures with an explanation

- Quantity Status – include the item types, shipment quantities, packed quantities and non-packed quantities

- Packing Method – attach pictures of the packaging and shipping marks.

- Product Conform-Check the appearance, accessories against approval sample or the document provided by clients.

- Data Measurement – score each section using conform’, ‘not conform’ or ‘pending’ and include the detailed measurements of each product.

- Field Test-According the checklist, perform all the test, including moisture check, stability heck, static loading check and other more. Attach all the test pictures.

- Additional Information – include any extra important information or pictures, including the factory gate, other document.

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.