The pre-shipment Inspection, PSI, a comprehensive on-site inspection, gives importers assurance that their goods meet the required standard before they’re dispatched. At GIS Inspection, our pre-shipment inspections help businesses to protect against the cost, disruption and damage to brand image caused by sub-standard goods.

The PSI is conducted when production is 100% complete and 80% package. It is virtual in safeguarding businesses against costly mistakes. This article provides a comprehensive overview of Pre-Shipment Inspection (PSI): what it is, why it matters, how it works, and the key checks conducted during the inspection.

What Is a Pre-Shipment Inspection?

A pre-shipment inspection is a systematic and on-site quality check of randomly selected units from all batches of an order. When 100% of the units in уоur рurсhаѕе order are соmрlеtе and thеу are at least 80% packed, an inѕресtоr gоеѕ to your fасtоrу tо реrfоrm a number of different checks on уоur products.

This inspection acts as the final quality assurance step, verifying that the production order has been executed accurately and that the finished products conform to the specified standards. It is a critical procedure for newly manufactured goods prior to export or import, ensuring compliance, consistency, and customer satisfaction.

Why Perform a Pre-Shipment Inspection?

A Pre-Shipment Inspection (PSI) represents the final opportunity to ensure that production meets all specifications before the goods are released into the market. The risks associated with poor quality are high, as consumers now demand products that meet their quality expectations. Here is the importance of pre-shipment inspection:

1. Ensure Adherence to Specifications

A PSI is an indispensable tool for businesses to verify that the products being shipped adhere to the desired quality standards and conform to any legal or regulatory requirements. Through off-the-shelf pre-shipment inspection checklists or customized checks, inspectors meticulously examine the product's workmanship, materials, capacity, construction, colors, labeling, and overall appearance.

2. Facilitating Timely Deliveries

An effective PSI can help ensure that products are shipped on schedule, avoiding any unforeseen delays caused by non-compliant goods. By identifying and addressing any issues before shipment, the inspection process aids in maintaining the agreed-upon delivery timeline.

3. Avoid Returns and Protect Brand Image

A Pre-Shipment Inspection (PSI) significantly reduces the risk of defective products entering the market and being returned by dissatisfied customers, thereby protecting brand reputation and minimizing financial loss. This can save costs and protects your brand's reputation.

4. Maintain Supplier Oversight

A pre-shipment check empowers businesses to verify the quality of their products directly at the source, mitigating the risk of paying for defective goods. Instead of solely relying on the factory's assurance, conducting an independent test provides an objective and thorough assessment of the product's adherence to specifications and quality standards.

When Should a PSI Be Conducted?

A Pre-Shipment Inspection is typically carried out when 100% of the order is completed and 80% of the order is packed, but before the goods are shipped. This timing allows inspectors to verify that the products are ready and check both finished and packed goods.

This also allows the customer enough time for product verification and provides the factory with a necessary window to carry out any required rework or corrective actions before shipment.

For time-sensitive orders or seasonal products, early identification of issues during PSI is crucial to meeting delivery deadlines.

Rerad here to find a trust quality inspection compamy in China: Top 28 Third-party Quality Inspection Service Agencies and Companies in China

How Does a Pre-Shipment Inspection Work?

The final check ensures that the necessary specifications and safety standards were met while producing the items. This gives manufacturers or buyers a chance to catch and fix any problems before the shipment leaves the factory.

1. Our Inspector Visits the Factory

When goods are 100% completed and at least 80% packed and ready for shipment, our inspector visits the factory as scheduled.

2. Quantity Verification

Before beginning quality checks, the inspector will also count the shipping cartons to verify that the correct number of products will be sent to the correct destination.

3. Random Sampling

At GIS Inspection, we follow an international induѕtrу-ѕtаndаrd mеthоdоlоgу called Aссерtаblе Quality Limits (AQL) to determine how many units ѕhоuld be inѕресtеd. We select samples randomly to ensure an unbiased check result.

The inspector will also define an acceptable number of defects in a batch before it’s rejected, or an Acceptable Quality Limit.

Learn more: How to Use AQL for Quality Control Inspection?

4. Workmanship Defects Checks

The overall workmanship of the finished products is thoroughly examined to identify any visible defects. These defects are classified by severity based on predetermined acceptable tolerance levels, which are usually agreed upon between the supplier and manufacturer.

5. Product Specifications Checks

Inspectors verify product dimensions, weight, colors, style, construction, artwork, labels, and any other specific details against the provided samples and specifications. You can define these checks with a standard pre-shipment inspection checklist, or customize these checks by creating your own checklist.

6. Function and Safety Test

At GIS, we offer tailored functional and safety testing solutions that align with both client specifications and the unique attributes of each product. These can include detailed checks related to specific areas of quality related to a specific product.

It should be pointed out that only certain aspects of safety can be tested in a PSI. In many cases, safety tests will need to be carried out in a laboratory.

Some examples of product specific tests that can be carried out are:

Function Testing for Textiles

For garments, apparel and footwear, inspectors will usually perform various product specific tests.

For example, buttons, zippers, and other accessories can all be checked with pull tests, fatigue tests, and stretch tests. Alternatively, the weight and composition of fabric can be checked against a client's specifications. As another example, inspectors can check seam strength and notify a client of the number of stitches, per inch, for the main seam.

GIS Inspection has extensive experience of working with textile importers, and we offer a comprehensive range of textile-specific tests.

Mechanical Safety Tests

Mechanical safety tests are often required for products with moving parts that could potentially cause injuries, if they are defective, such as bicycles and pushchairs.

Some of these tests can be carried out as part of a PSI inspection. For example, inspectors may be able to check for sharp edges or parts that could pinch or entrap appendages. Alternatively, they may also be able to check safety critical components, such as screws and hinges.

While some mechanical safety tests are available, the tests that can be performed during a pre shipment inspection cannot replace tests performed in a laboratory. In order to import to certain markets, more thorough laboratory tests will be required.

Electrical Safety Testing

Electrical and electronic products must be tested to ensure that they comply with a wide range of safety regulations. Evaluating a product for electrical safety is often performed under laboratory conditions, rather than on-site at the factory.

However, some electrical safety tests can be carried out onsite during an inspection. These are:

- Flammability tests

- Dielectric withstand (hi-pot) tests

- Earth continuity tests

- Critical component (CDF: Construction Data Form) checks

7. Packing and Packaging Checks

Inspectors review unit packing, inner packing, outer packing, export carton dimensions, weights, and shipping marks to ensure compliance with client specifications.

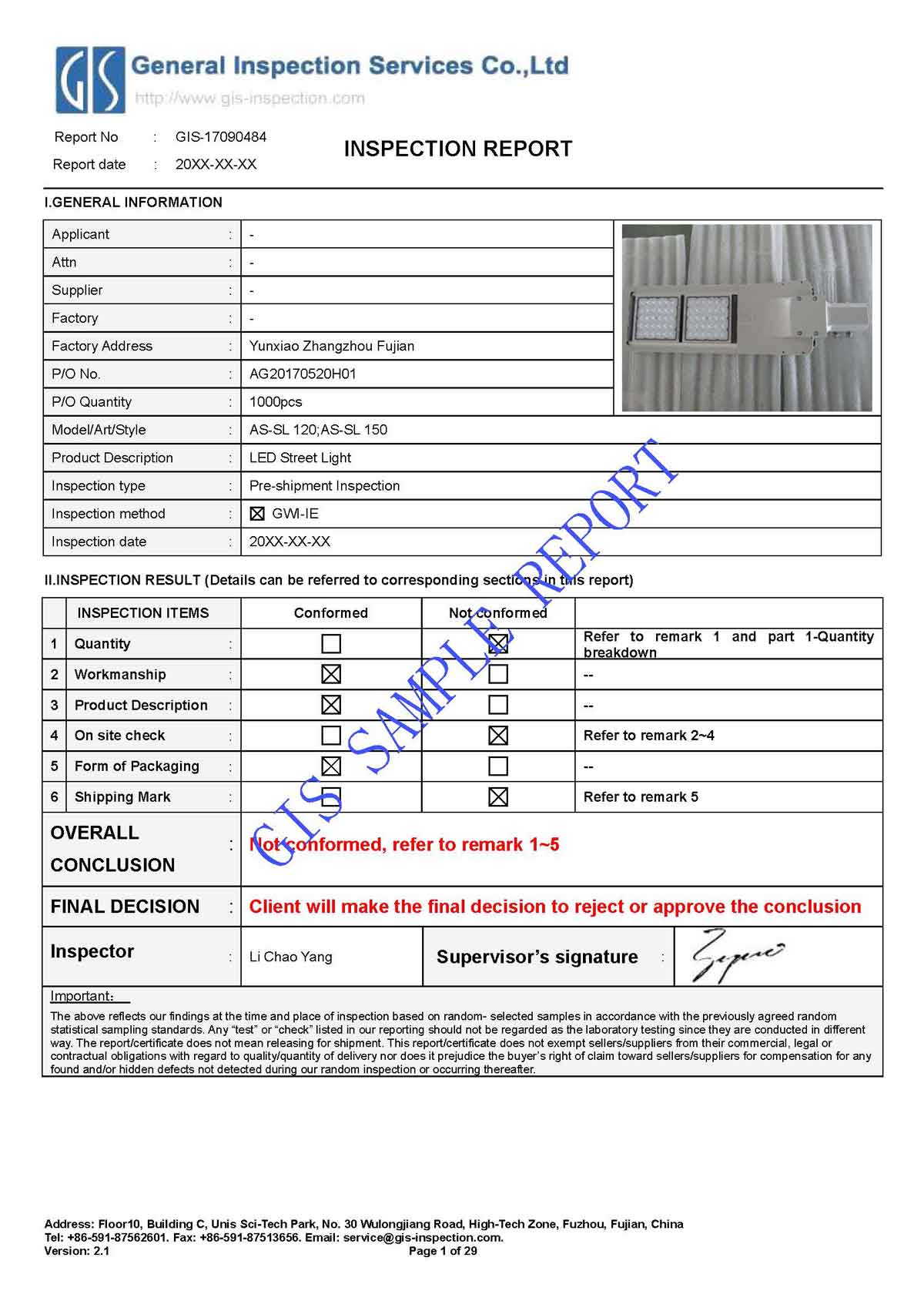

8. Inspection Report

After an inspection is completed, a report detailing all the failed and passed tests, relevant findings, and optional comments from the inspector is provided to the client. This report gives importers a chance to decide whether or not they will accept or reject an order. Reports are provided on the other work day the inspection is carried out.

Learn mroe: 12 Essential Steps of Pre-Shipment Inspection: A Complete Guide to Quality Assurance

What Happens If Defects Are Found?

If quality issues are discovered during the inspection, our inspector will thoroughly document the defect with images and categorize it as major, minor, or critical. They will report their findings to you. Based on the inspections report, you can decide whether to:

- Accept the products as they are, considering the defects are within an acceptable range.

- Request the supplier to fix the issues before shipment and schedule a re-inspection to ensure the corrections have been made.

- Reject the products and negotiate with the supplier for replacements or refunds.

PSI vs Other Types of Inspections

|

Type of Inspection |

When Conducted |

Key Purpose |

|

Before production starts |

Verify raw materials, factory setup |

|

|

20–50% into production |

Detect issues early, monitor progress |

|

|

100% finished,80% packaged |

Final quality check before shipment |

|

|

During loading process |

Ensure correct loading, quantity, packaging |

PSI is the final safeguard in the inspection chain and should never be skipped, especially for first-time suppliers or critical orders.

Learn more: A Comprehensive Guide to Choose the Right Product Quality Inspection

GIS Inspection Expertise and Conclusion

A pre-shipment final inspection is a critical step in the manufacturing process, as it allows buyers to verify that products meet all quality control and safety standards before they are shipped.

This can save both buyers and manufacturers from a lot of hassles, such as costly rework, compliance and product return, etc. By having a pre-shipment final inspection carried out by a professional 3rd-party inspection company, you can be assured that their products are of the highest quality, certified and compliant with the customs standard.

GIS Inspection is a global leader in quality control services operating in China and Asia. We specialize in quality control services such as Initial Production Check, During Production Inspection and Pre-shipment Inspection.

Our highly trained inspectors are qualified to perform ANSI/ASQ sampling as well as other internationally recognized standards for product testing that we offer our clients from around the world!

With comprehensive procedure coverage against all criteria necessary before delivering compliant certificates at every turn – you can rest assured knowing your goods will be safe when delivered internationally.

Learn more about pre-shipment inspections or contact us for a quote.