Defect photo-GIS pre shipment inspection for clothing in China

Buying from China? Ensuring your shipment meets regulations and quality standards is essential for a successful business. Noncompliance with these requirements can lead to costly delays or even rejections.

A pre-shipment inspection, conducted by a third-party inspection company, ensures that the goods meet all required standards and adhere to the terms outlined in the purchase order or letter of credit. By identifying potential discrepancies or defects before goods leave the supplier, importers significantly reduce the likelihood of receiving low-quality or malfunctioning products.

In this blog post, we’ll explore what pre shipment inspection is, the steps involved, China pre-shipment inspection cost, how to schedule a PSI inspection, and top China inspection companies.

Content

What is pre-shipment inspection (psi)?

Why is it important for exporters?

Importer voluntary pre-shipment inspection: the essence of psi

Steps involved in a pre-shipment inspection

Pre-shipment inspection checklist

Step-by-step guide to scheduling a pre-shipment inspection

Top 28 pre shipment inspection service agencies and companies in china

What is pre-shipment inspection (PSI)?

A pre-shipment inspection (PSI) is a quality control check that is performed before a goods consignment is shipped to its destination. Third party PSI inspection in China is normally conducted when product production is 100% completed and at least 80% packaged.

It is a critical step in verifying that your goods meet quantity, quality, safety, packaging, and labeling standards before leaving the supplier’s facility. The process also offers manufacturers a chance to address and fix any issues before shipping, thereby reducing the risk of exporting defective or non-compliant products.

Backed by twenty years of experience, GIS Inspection is recognized as a leading provider of quality assurance and inspection services in China.

Why is it important for exporters?

Pre-shipment inspections are a critical step in ensuring goods meet quality and regulatory standards before leaving China. This proactive approach allows businesses to minimize risks associated with costly delays caused by quality issues, unexpected returns or replacements, and damage to customer relationships.

Compliance with Regulations

Pre-shipment inspections confirm that the goods being exported meet desired quality standards, and adhere to legal or regulatory. Each item must meet specific requirements. Failing to meet these standards might lead to significant delays and additional fees, consequently hindering your overall operations./hide automatically.

Ensuring Quality

Guaranteeing the quality of your goods is an inseparable step in pre-shipment inspections. It helps prevent defective or subpar products from reaching your customers, which, of course, could harm your brand reputation, leading to financial losses. By inspecting goods before they are shipped, you ensure that they meet your brand’s standards./hide automatically.

Reduces risk

Pre-shipment inspections help mitigate risks associated with international trade. Importers face a lower likelihood of receiving inferior goods, while exporters and manufacturers can avoid potential reputational harm and additional costs which may arise from the shipment of defective products./hide automatically.

Enables prompt deliveries:

An efficient pre-shipment inspection helps ensure timely product deliveries by preventing unexpected delays caused by non-compliant products. This allows trading partners to uphold their obligations and retain a favorable relationship with one another./hide automatically.

Importer voluntary pre-shipment inspection: the essence of PSI

Unlike government-required pre-shipment inspections that emphasize import tariff classification, voluntary pre shipment testing focus more on verifying that the quantity, specifications, and quality of the goods are consistent with the contract.

I would say that voluntary pre shipment inspection is the essence of PSI, as it exists to reduce the risk for importers.

What is the need of pre shipment inspection?

Pre-shipment inspection is actually like some kind of insurance. As an importer, you pay a small cost to avoid significant losses if a problem occurs.

With new suppliers, most buyers are aware of the need for product inspection before shipping. The problem lies with suppliers who you have worked with a few times with no major quality issues.

Defect found in when pre-shipment in China

A buyer from Brazil contacted GIS Inspection to arrange a pre-shipment inspection after receiving serious customer complaints from the last shipment, which had not been inspected before payment. The following facts are why we recommend performing pre-shipment inspections for your current suppliers:

- Your supplier does not perform in-house inspections

- Unclear supplier internal quality checklist

- Your supplier is a factory, but the SKU you ordered may not be produced by them

- Due to the price increase of raw materials, suppliers change materials to keep product prices the same

ISO 2859-1: An Internationally Recognized Pre shipment Inspection Standard

In 1999, ISO ( International Organization for Standardization ) published ISO 2859-1 standard, which specifies sampling procedures for inspection by attributes — “-1” means “Part 1” which is about “Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection”

What’s your takeaway? If your candidate inspectiopre testing n agency can’t specify what standard they follow for product inspection, they likely don’t comply with any of those. No matter how good their inspection costs are, this is the last company you want.

AQL (Acceptance quality limit): The basis for an effective pre-shipment inspection

What is AQL? AQL (Acceptable Quality Limit) is defined by ISO 2859-1 as a “quality level that is the worst tolerable” and is used to determine the maximum number of defects that can be accepted during a pre-shipment inspection.

It’s pretty straightforward to understand. Imagine finding a major defect in 10,000 or 10 products, and their quality levels are completely different.

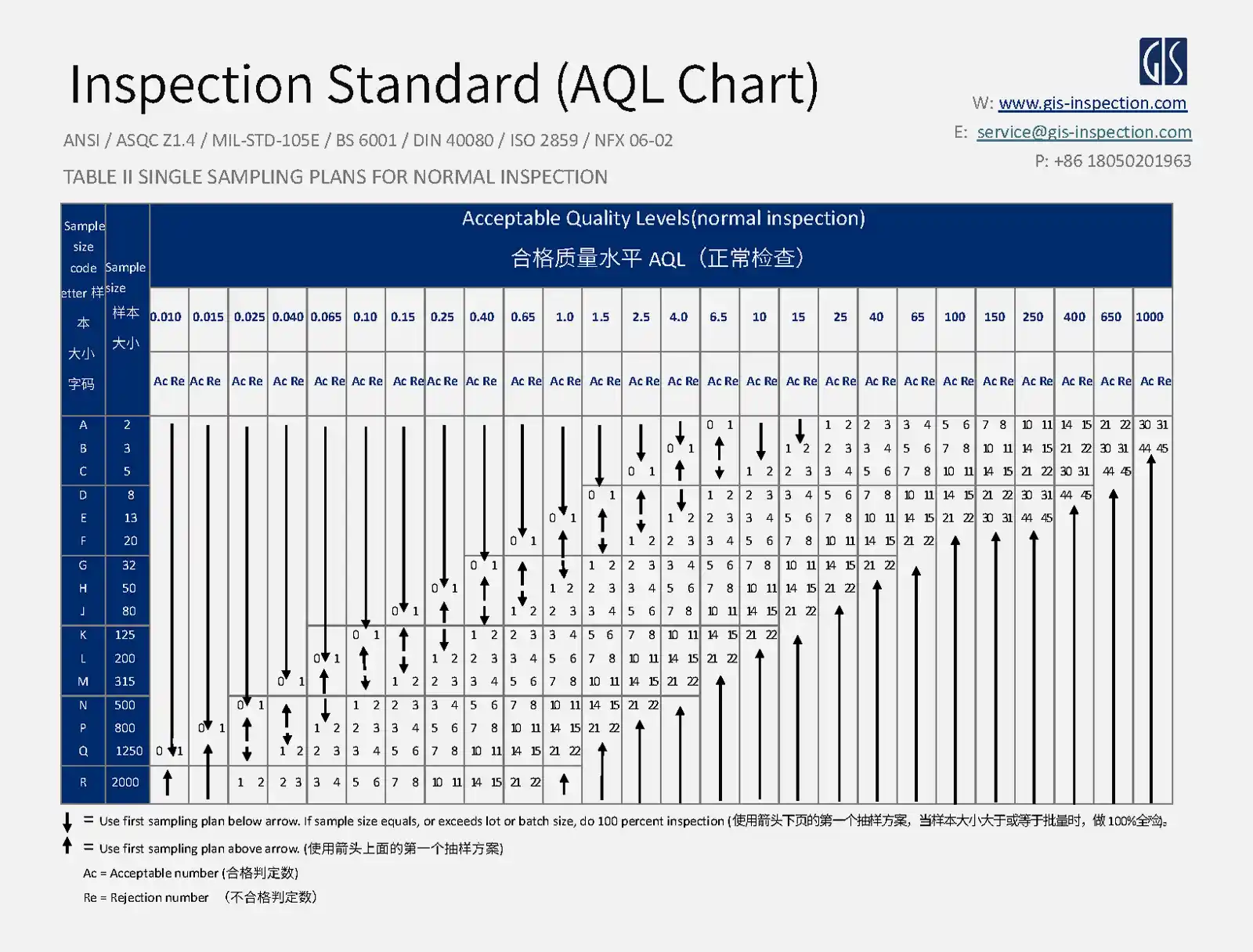

Sampling plan: Implementation plan for pre shipment inspection

If AQL is considered the theoretical basis, then the sampling plan is the detailed implementation plan for pre-shipment inspection. Every pre shipment inspection has its own sampling plan, and each sampling plan is a combination of sample size as well as acceptance and rejection numbers.

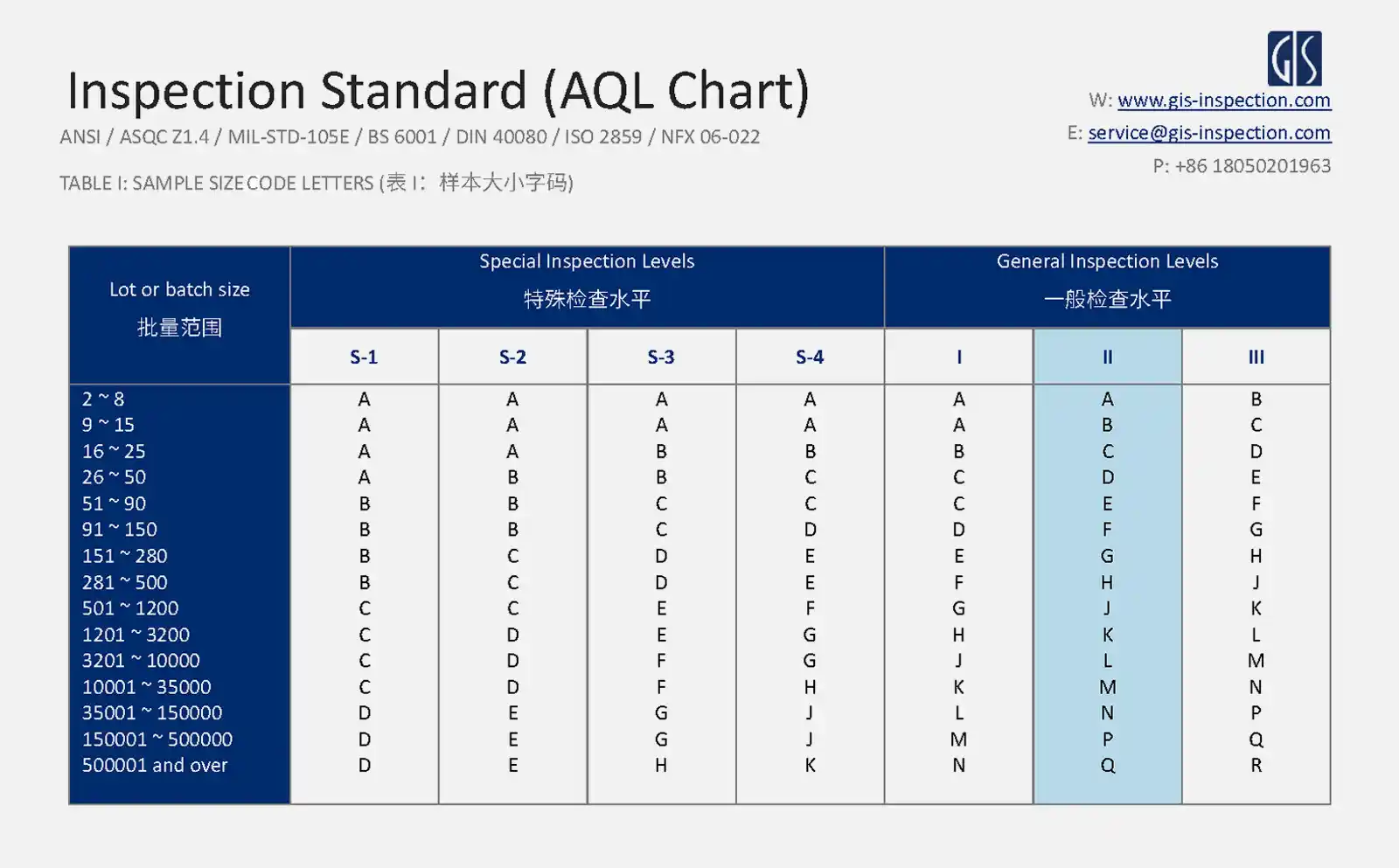

For instance, suppose the lot number of your products is 4,000. Under the default AQL General Inspection Level II, the corresponding code letter is N, which means a sample size of 500 pieces. Completing this pre-shipment inspection would typically require two man-days.

However, if you're confident in the supplier's reliability and wish to save both time and inspection costs, you could opt for General Inspection Level I instead. In this case, the sample size drops to 200 pieces for the same total order quantity, allowing the inspection to be completed within one man-day.

Inspection level: fine-tune your pre-shipment inspection for the same lot size in different cases

The AQL inspection level designates the amount of inspection used in different scenarios.

ISO 2859-1 specifies three general inspection (Level I, Level II and Level III) and four special inspection (S-1, S-2, S-3 and S-4)standards.

Usually, Level 2 is the default choice. However, suppose your supplier has a good quality record. In that case, you may also consider Level 1 to save inspection costs and time, or if they have just had a major quality problem, you should consider Level 3 to check more samples.

In a random inspection, the inspector may find several nonconformities, which are non-fulfillment of a specified requirement. When the nonconformity affects the product’s intended use, it becomes a defect. ISO defines different defects according to their seriousness as Class A and Class B.

But at third-party inspection companies, a more common defect classification method is: critical, major, and minor.

AQL table for random sampling inspection in China

How are these defects classified? What are the criteria for classifying defects in pre-shipment inspection?

- Critical - A critical defect is on that judgment and experience indicate is likely to:a. result in hazardous or unsafe conditions for individuals using, maintaining, or depending upon the products; b. prevent performance of the tactical function of a major end item.

- Major - A major defect is one, other than critical, that is likely to result in failure, or to reduce materially the usability of the unit of product for its intended purpose.

- Minor - A minor defect is one that is not likely to reduce materially the usability of the unit of product for its intended purpose, or is a departure from established standards having little bearing on the effective use or operation of the unit of product.

The AQL chart consists of two tables as below you can see.

AQL Chart: Table 1-Sample Size Code Letters

AQL Chart: Table 2- Single Sampling Plans for Normal Inspection

The AQL standards for products vary across industries. For instance, electrics product are more likely to have more stringent AQL then textile and apparel products due to higher safety risks and technical complexities.

Third-party inspection companies like GIS Inspection typically use AQL (Acceptable Quality Level) standards when conducting product inspection in Asia. The specific AQL levels chosen depend on the product type, quality requirements, and customer expectations.

Discover how qualified third-party commonly applied AQL standards for different industries during quality control inspections: How to Use AQL for Quality Control Inspection?

Adjust PSI inspection level according to the supplier’s status

In simple terms, if your supplier has a proven record of consistent product quality, you may consider reducing the level of pre-shipment testing.

Steps involved in a pre-shipment inspection

The quality assurance final random inspection ensures that the products meet quality standards before shipment, ultimately protecting both buyers and suppliers.

There are 12 important procedures that GIS pre-shipment inspection service performance:

- Confirm the Inspection Criteria and Sampling Plan: Confirm inspection date, sampling method, product checklists, and inspector.

- Opening Meeting: Have an opening meeting with factory.

- Quantity Verification: Count products and shipping cartons to verify that the correct quantity of an order has been finished.

- Random Sampling: Select a sample size according to the statistical sampling procedure ISO 2859-1.

- Product and Verification: Verify that the products conform to the specifications against PO, photos, and sample.

- Workmanship Check: Conduct a visual check for any damages and flaws in workmanship.

- Size Measurement Check: Check or measuring the important data/parameters which reflect the product quality or performance.

- Function Test: The product is put to use to check if it works as intended. Any functional defects are identified and noted.

- Safety Test: A safety test includes a mechanical and an electrical component. For example, conduct Hi-pot check, earth continuity check, temperature measurement, stability check, internal check for electrical.

- Packaging Check: Check the packing method and packing information to ensure that everything is accurate and safe for transportation.

- Close Meeting: Have a close meeting to get factory’s confirmation.

- Inspection Report: After completing the inspection, GIS Inspection will provide you with detailed and unbiased inspection reports and certificates, verifying whether the products meet the specifications stated in your contract.

Pre-shipment inspection checklist

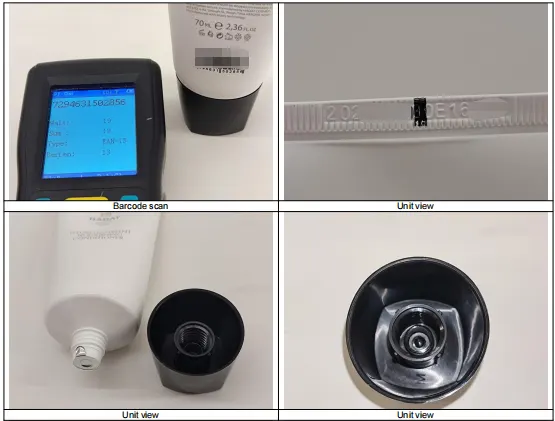

Source: Inspection photo showing GIS verifying shampoo product quality for a Russian customer.

A comprehensive PSI inspection checklist is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

1. Quantity Verification:

Verifying that the correct number of units are packed and marked for shipping.

2. Workmanship Check

To do this, inspectors look for and report on the presence of defects that are common on certain products. Defects, such as blemishes in finishes, cracks, sharp edges, color inconsistency, stains, chips or holes are all reported. This is along with the frequency of their occurrence across a sampled batch.

The most important and lengthy part of a pre-shipment inspection is the check of workmanship quality. The inspector will select a sample size according to the statistical sampling procedure ISO 2859-1, and conduct a visual check for any damages and flaws in workmanship and classify them as major, minor, or critical defects based on predetermined acceptable tolerance levels.

Defects, such as blemishes in finishes, cracks, sharp edges, color inconsistency, stains, chips or holes are all reported. This is along with the frequency of their occurrence across a sampled batch.

3. Product Description

Inspectors verify product dimensions, weight, colors, style, construction, artwork, labels, and any other specific details against the provided samples and specifications. You can define these checks with a standard pre-shipment inspection checklist, or customize these checks by creating your own checklist.

Ensuring conformity with design and construction standards is critical for maintaining brand integrity and customer satisfaction.

4. On-site Check

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards. This includes various tests such as pull tests, fatigue tests, and stretch tests for apparel and garments, and safety tests for electronics and mechanical products.

5. Packaging Check

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

Learn more: Pre-Shipment Inspection (PSI): Everything You Need to Know

Step-by-Step Guide to Scheduling a Pre-Shipment Inspection

GIS Inspection offers comprehensive pre shipment inspection services in China. If you’re planning to import goods from China, we’re here to assist you in managing the pre-shipment inspection as part of your shipment arrangement.

Here’s a breakdown of how it works, every step of the way:

1. Booking the Service:

Contact our sales and write a booking. It's very important to clearly communicate your order details, inspection plan, and specific inspection requirements with our team, so that we can ensure the inspection is carried out accurately and according to your expectations./hide automatically.

2. Scheduling the Inspection:

After your booking is confirmed, our team will get in touch to set up the inspection date. We'll work with your supplier to make sure the inspection takes place when 100% of your goods are produced and at least 80% packed./hide automatically.

3. Conducting the Inspection:

A qualified inspector will visit your supplier's facility to perform a detailed inspection of your goods. They'll assess important aspects such as quantity, product appearance, functionality, workmanship, packaging, labeling, and regulatory compliance./hide automatically.

4. Getting Your Inspection Report:

You'll receive a detailed report within 24 hours of the inspection, which includes findings, photos, and any issues identified. This helps you make informed decisions about your shipment before it leaves the supplier's facility./hide automatically.

After reviewing the inspection report, you can choose to approve the shipment, ask the supplier for corrections, or take other necessary steps to ensure the goods meet your standards before shipping.

Check a Free Report Sample for Pre-shipment Quality Inspection in China!

Top 28 Third-party Quality Inspection Service Agencies and Companies in China

There are a lot of companies in China that can provide pre-shipment inspection, which including global company like SGS, Eurofins, as well as local agency like GIS Inspection. We list the top 28 of China pre-shipment inspection and attached their main service and contact Infor:

| No. | Company | Location | Main Service |

| 1 | GIS Inspection | Fujian China | Quality Inspection, Factory Audit |

| 2 | SGS | Switzerland/Shanghai, China | Testing, inspection, certification |

| 3 | TÜV Rheinland | Germany/Beijing, China | Testing/assessment, certification/auditing, training, inspection/Supervision, consulting/project management |

| 4 | TÜV SÜD | Germany /Shanghai, China | Testing and product certification, Auditing and system certification, Inspection, training, advisory |

| 5 | Intertek | UK,China | Assurance, Testing, Inspection, Certification |

| 6 | eurofins | French / Shanghai, China | Analytical testing services in food, environment, pharmaceutical and cosmetic product |

| 7 | UI | Beijing, China | Certification, testing |

| 8 | Bureau Veritas | French | Testing, Inspection and Certification |

| 9 | DEKRA | Germany | vehicle inspections, industrial inspections, appraisels, product certifications |

| 10 | Pro QC | America/Shenzhen | Product quality, factory & supplier audits, management system audits |

| 11 | Tetra Inspection | Shenzhen, China | Product inspection, supplier audit, Certificate |

| 12 | Cotecna | Switzerland/Shanghai | Tailor-made inspection, audit, certification and testing |

| 13 | Sofest | HongKong,China | Supply chain management, product engineering, quality assurance |

| 14 | AQI Service | HongKong,China | Product inspection, audit and testing |

| 15 | CCIC | Beijing, China | inspection, identification, certification and testing |

| 16 | CTI | Shenzhen, China | Testing company in China,Testing, certification, inspection, training, audit |

| 17 | CIS China Inspection Service | Hong Kong, China | Inspection company in China, Factory Audit and Product Inspection services |

| 18 | AmSpec | Hong Kong, China | Testing, inspection, certification |

| 19 | Vicc | Beijing, China | Inspection company in China, Inspection, audit, testing, certification |

| 20 | VIS Quality Control | Vietnam | Inspection company in China, Inspection, audit, testing, certifications |

| 21 | Global Inspection Managing | Product inspection, factory audits | US/Shenzhen, China |

| 22 | QGS | Hong Kong, China | Product quality inspection services, factory audit |

| 23 | Applus+ | Spain / Shanghai, China | |

| 24 | AQF | Shenzhen, China | Product Inspection, Factory Audit, Lab testing |

| 25 | Insight Quality Services | Dallas-Fort Worth Metroplex | Product Inspection, Factory Audit, Lab Testing, Training & Consulting, Correct & Rework |

| 26 | TradeAider | hangzhou, China | Product Inspection, Total Quality Control Services(TQC/TQM), Amazon FBA Inspection Solutions |

| 27 | ECQA | Shanghai, China | Inspection, Testing & Certificate, Sourcing |

| 28 | NBNQC | China | Product inspection, Manufacturing Audit, Social Audit |

How much does pre-shipment inspection cost

There is no standard price for pre-shipment inspection. What can be confirmed is that professional third-party inspection companies calculate their fees based on man-days.

Pre shipment inspection cost in China

Usually, the cost range for arranging a pre shipment inspection in China is $120 to $300 per man-day. On average, this pays for 8-12 hours of product quality inspections time.

Most third-party QC providers, including GIS Inspection, will bill you for their inspection services using what are called “man-days”. Man-days are a unit of time for measuring how long one inspector is needed for a service. The number of hours in a man-day can vary by QC provider.

- QC inspection budget

- Traveling to the factory or inspection site (often for an hour or more)

- Preparing the inspection area, which can vary depending on the readiness of the facility

- Pulling a random sample of goods (when using acceptance sampling)

- Writing the inspection report on-site

- Submitting the report to technical staff in the home office for review and approval

- Returning from the factory or inspection site

All of these activities take time and all contribute to the time allotted in a standard man-day. It’s a 12-hour job that involves a lot more than one typically thinks. And depending on the time needed for these, your inspector may have less time to actually examine and test your product than you might expect.

In addition to labor costs, travel expenses may also apply if the factory is far from the nearest importer.

MAN-DAYS DEFINITION

This general man-day definition: "a unit of one day's work by one person" seems to be the most suitable for all cases. In the quality control industry, the man-day is considered as a workload unit, which is very similar. From the buyer's point of view, the "man-day" is a system that allows direct and quick QC cost calculations.

"Man": both women and men work as inspectors. Qualified staff is crucial for reliable quality control. Inspectors spend their time checking products quality and conformity in factories in order to protect the importers' interests.

"Days": a meaningful inspection takes four to six hours. Inspectors should only perform one QC per day, to ensure reliable results.

What If Your Budget is Low?

What can you do if the budget is too high (maybe your entire order is worth $500)?

Here Are Some Alternatives:

- Find some companies that charge low fees ($150, GIS Inspection), but you need to keep your eyes open and carefully identify the quality of their services. Most of them may be party time inspectors.

- Ask the supplier for many photos and possibly a live video showing many photos (easy for WeChat in China).

- Ask the supplier to send you some production samples.

- Maybe you can’t buy “Chinese products” directly while keeping the risk low. You need to work with wholesalers.

For most importers, cost is a major factor. You probably don’t want to take the chance of shipping your goods to customers without verifying the quality first. At the same time, you don’t want to pay more than necessary to get a reasonable inspection scope.

Managing costs can be challenging for importers working with one of dozens of professional QC providers offering their services. The best QC provider for you may be one that’s conscious of your budget and willing and able to work with you to accommodate it.

Conclusion

A pre-shipment inspection is a valuable quality control mechanism that helps exporters deliver high-quality products and maintain positive relationships with buyers. This process is significant for buyers shipping products to foreign markets as it helps prevent the inconvenience of additional expenses, delays, or customer complaints resulting from defective products.

GIS Inspection is a certified and reliable third-party agency specializing in pre-shipment inspections. We act as your trusted partner, ensuring your supply chain are handled efficiently and professionally.

FAQs

Discover the answers to the most frequently asked questions about conducting pre-shipment inspection service for your businesses.

Q1: When Should Your Schedule a Pre-Shipment Inspection in China?

Your pre-shipment inspections should be arranged to take place when at least 80% of the products are produced and packed at the supplier’s facility. This timing ensures a meaningful assessment of the goods while allowing any necessary adjustments to be made before shipping.

When businesses search for the best pre-shipment inspection company in China, they look for reliable coordination and efficient support—key strengths of Ship4wd.

The inspection is scheduled as part of the shipment booking process, ensuring everything is planned in advance. Ship4wd works closely with your supplier to coordinate the inspection at the right time, helping to identify and address any issues promptly. This ensures your goods meet quality standards and avoids potential delays or disruptions to your business.

Q2: How to Arrange a China Quality Inspection Service?

When you are going to arrange for a quality inspection of your product in China. You need to you must clearly communicate the following information to your inspection company and QC inspectors:

- Supplier contact information, factory address (otherwise, they will ask for it from the supplier)

- Product description, photos, maybe a short video

- Description of packaging

- State your quality standards and what you can/can’t accept.

- Quantity classification (for example, if there are multiple models, sizes, or colors, they need to know)

Also, if possible, make sure they have physical samples on hand. It’s helpful because some aspects of touch and feel don’t communicate well, even in the video.

Q3: What Happens if Issues are Found During the Inspection?

That may happen, however, if we do find any concerns that need to be addressed, you will have sufficient time to ensure your goods are supplied as they should. The corrections may involve rectifying labeling errors, replacing damaged goods, or resolving any quality control issues.

Q4: Can Pre-Shipment Inspections in China Be Customized for Specific Goods?

Yes, pre-shipment inspections can be tailored to specific products based on the unique requirements of your business or industry. For example, manufacturers might need to ensure material quality, while e-commerce businesses will focus on packaging and labeling standards. Your freight forwarder can help coordinate the right inspection criteria for your specific goods.

Q5: What Happens if My Report Fail in a Pre-Shipment Inspection?

A failed pre-shipment inspection highlights potential problems before your goods are shipped, giving you and the supplier a chance to find solutions. The specific actions taken will depend on your contract with the supplier and the nature of the issues discovered.

After receiving a detailed report from the pre-shipment inspection pointing out all defects, quantity discrepancies, packaging problems, or other non-conformities, you’ll carefully review this against the terms of your contract.

You’ll then communicate these findings directly to the supplier, requesting corrective action before the shipment can be released.

The supplier will assess whether the identified problems can be resolved within your agreed-upon timeframe. If so, they’ll work to make necessary corrections. You may opt for a re-inspection (coordinated through your freight forwarder) to verify that the issues have been addressed satisfactorily.

If the issues cannot be resolved in time or to a mutually agreeable standard, you’ll need to explore other options outlined in your contract. This might include negotiations for discounts, partial acceptance of the shipment, or, in the most severe cases, potential rejection.

Remember, a strong contract is your most important tool, as it clearly defines your expectations and outlines possible solutions in case of discrepancies.

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.