Buying coffee machine from Asia? Getting your customers a high-quality coffee maker is one of the tasks of an importer.

There are several varieties of coffee makers in the marketplace like manual espresso maker, capsule coffee machine, drip coffee maker, semi-automatic espresso machine and more, they all require a comprehensive inspection checklist to ensure the quality, function, and endurance are working as expected by the final customer.

Pre-shipment inspections, during-production inspections, and pre-production inspections are usually performed during each step of coffee machine manufacturing. How to inspect Household coffee machine before shipping?

The 6 checklists for conducting pre-shipment inspection for coffee machine by GIS Inspection

With reference to IEC 60335-1, ANSI/UL 1082, and IEC 61661, GIS inspection electrical and electronic technicians have developed a comprehensive inspection checklist for coffee makers to help clients ensure product quality and avoid recall risks.

Below are the checklists performed by our expert inspectors during the pre-shipment inspections for coffee machine.

1. Packing checking: gift box, carton, pallet

- Material, packing: Visual check. Without, scratches, dirty, poor printing, damage etc..

- Sealing: Good closed/sealed

- Straps: Good strap

- Appearance ( Photo, outside and inner): Visual check. without damage, crutches, dirty etc.

- Printing and label; Bar code label; Logo, mark and any printing; logistic information label and other label: Marking or label clear, right position etc

2. Appearance and Workmanship Check

The cosmetic check should be conducted under good illumination condition. For color comparison, it should be conducted under natural sunlight or daylight lamp. During the checking, Inspector views the product with about one arm distance (or other specified distance agreed by client) and provides a detailed visual assessment.

If defect is not visible then considered as acceptable. If defect is visible then classify it as major or minor defect based on the statement in Defect Classification List.

- Material: Verify the material of coffee maker.

- Appearance: No dirt, rust, damage, crack, wrong/missing mark, scratch, rough surface, wobble base, loose part, white stress mark, shrink mark, mold mark, gap existed, broken, improper fitting, etc;

- Dimension

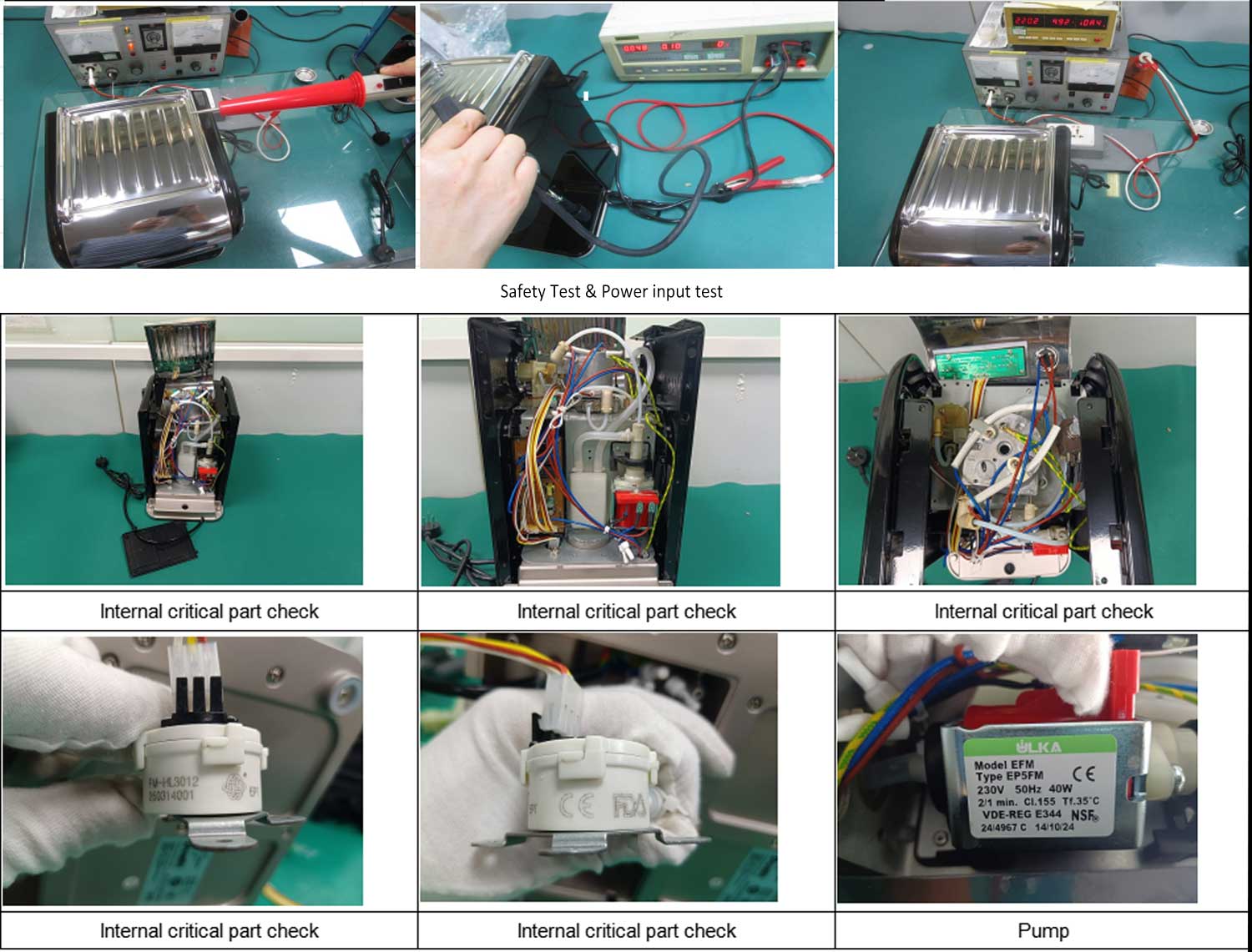

3. Safety Check

Conducted the check refer to relevant product safety standard such as local rules, CCC, CE, UL, REACH and more, to ensure the product in safe condition for an individual using and comply with legal, regional mandatory regulations.

Hi-pot check: Apply single phase voltage between live and accessible parts of the entire product, mains switches and any functional switches conductivity connected to the mains in on position.

Earth continuity check: Resistance between accessible earthed metal parts of the entire product and ground blade or pin of the plug/socket or earth wire should be no more than 0.1Ω at 12V, 25A.

- Stability check:

- EU Standard: Not tip over on a 10˚ panel.

- UL Standard : At 15 degree plane

- Strain relief check:

- For USA: Cord withstand for 1min with a pull of 35lbs (156N), without displacement. (ANSI UL 1082)

- For EU: The cord pull 25times and 1sec for each time, the power cord displacement<=2mm, the force as below:

- Product<1kg, pull force 30N

- 1kg<Product<4kg, pull force 60N

- Product>4kg, pull force 100N

- (IEC 60335-1)

- Internal check: Comply with CDF, no non-compliant component and safety issue, check any soldering issue happened on internal component such as short circuit, false solder…etc

- Dry boiling test: Fuse should not damaged after thermostat cut-off.

- Thermal fuse check: fuse should cut-off when short the thermostat, no safety issue occur.

4. Functional Check

Functional checks should be conducted accord all of the intended features and performances stated in the purchase order; client approved specification, instruction manual, and selling point on unit, factory specification etc.

- Basic function: Fill water tank with water, check the basic function of unit, as button or switch, LED screen, indicator light function, and so on. No drop when glass jar is raised up.

- Full function check:

- Check full function against instruction manual, package artwork.

- Note down total operation time ;

- The moment at which the period between two drops falling consecutively into the coffee container is approximately 2 s;

- At the half of the cycle, the jar is removed for 20 seconds, maximum allow 3 drops on heating plate.

- Input power consumption: Turn on the coffee machine with rated voltage, record the power consumption.

- Keep warm check:

- Note down the temperature at the end of coffee flow.

- The coffee container is put on the warming device again. The temperature of the liquid is measured again after 30 min and 60 min

5. Special Check

- Drop test(1 ctn / item, no less than 3 ctns in total):

- No safety issue; Each inspected product is free from damage or malfunction; Salability of any gift box is not affected; The master carton still affords reasonable protection to the contents.

- Conformity certificate, label, specification data or instruction:

- Rub and tape check:

- 15s with a piece of cloth soaked with water, then for 15s with a piece of cloth soaked with Hexane.

- Tape test use 3M810 tape

6. Data Measurement

Check or measuring the important data/parameters which reflect the product quality or performance according to legalized method or stated in client approved product specification or other agreed documents by client.

- Power cord length measurement: Note down data

- Carton measurement: Conformance per printed information. Follow client tolerance to determine the result.

- Barcode check: Must be able to scan and barcodes are correct as printed. Successful read out should achieve at over 3 out of 5 times of scanning for barcode on gift box or carton box.

- Others: Note down ambient temperature and humidity.

Defect Classification List

|

Potential defect classification |

Cr |

Ma |

Mi |

|

Incorrect polarity |

x |

|

|

|

Broken wire |

x |

|

|

|

Dead bulb (if included) |

|

x |

|

|

Others |

x |

x |

x |

- Critical Nonconformity (Defect) - A defect which experience and judgment indicates is likely to result to result in a hazardous and / or injurious situation to the user, or makes the product subject to governmental seizure

- Major Nonconformity (Defect) - Any unit having nonconformity (defect) other than critical is likely to result in failure, or to reduce materially the usability of the unit for its intended purpose, or any unit having an aesthetics nonconformity (defect) which affect the salability of the products, or as per applicant’s requirement.

- Minor Nonconformity (Defect) - Any unit having nonconformity (defect) that in not likely to reduce the usability of the unit for its intended purpose, or is departure from established standards having little bearing on the effective use of the products.

GIS Inspection Quality Inspection for Coffee Machine

GIS Inspection is a leading third-party quality inspection agency in China. With 20 years of experience, we are experts in electric product inspection and quality assurance. The checklist is designed to support clients in verifying product compliance, ensuring safety, and avoiding potential recalls.

GIS Inspection conducts comprehensive pre-production inspection, during production inspection, and pre-shipment inspections, following the AQL standards, leaving no room for subpar products to slip through the cracks.

Our coffee machine inspection report comes with digital evidence, enabling efficient identification, categorization of defects and recommendations. With GIS Inspection, you can expect timely and detailed inspection reports, allowing you to take prompt action if any issues arise.

Sourcing across Asia is not without communication and language barriers, with Vietnam, India and China fast becoming a popular destination for furniture manufacturing due to the low costs. Using GIS Inspection, a professional third-party quality provider, who has the expertise in inspection and sourcing can ensure you will receive the best, top-quality products, as product specifications can be communicated correctly and clearly.

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.