Buying outdoor textile from China and Asia? By employing a third-party inspection entity, quality concerns will be identified and controlled at the source.

An outdoor textile inspection can help to identify any defects or non-conformities in the batch, allowing for corrections before the products reach the customer, thereby safeguarding the buyer’s reputation and minimizing the risk of costly returns or complaints.

Contents:

What is an Outdoor Textile Quality Inspection?

Outdoor Textile Quality Inspection is a comprehensive process of checking outdoor textile for fabrics, durability, functionality, and safety to ensure it meets specified standards and regulations.

Random quality inspections of outdoor apparel and sports textiles during production and before loading is critical to safeguard the quality of the products and ensure end consumers’ satisfaction.

Also called quality control (QC), on-site inspection is often used by buyers to examine the quality of outdoor textile goods and receive an objective report detailing the results to help make a shipment decision.

Standard Used in the Outdoor Textile Inspection

Fabric Colorfastness Testing

Colorfastness is a crucial quality aspect, determining whether a fabric’s color will bleed or fade under various conditions. Tests are conducted for colorfastness to washing (ISO 105-C06), rubbing (ISO 105-X12), and light exposure (ISO 105-B02).

EN ISO 5912:2020 Camping tents. Requirements and test methods

Camping is a beloved activity that brings people closer to nature, but it also requires reliable equipment to ensure safety and comfort. The EN ISO 5912:2020 standard is designed to provide a benchmark for the quality and safety of camping tents. By adhering to this standard, manufacturers can guarantee that their products are fit for purpose, durable, and safe for consumers.

ISO 23537-1:2022 Requirements for sleeping bags

ISO 23537 standard specifies the requirements, test methods and other provisions for the labelling of adult sized sleeping bags for use in sports and leisure time activities at a limit temperature ≥ ‐20 °C regarding thermal characteristics, dimensions and mass.

What is an Outdoor Textile Pre-shipment Inspection?

An outdoor textile pre-shipment inspection is a quality control process conducted prior to shipment to confirm that the products meet specified standards and customer requirements. It involves checking the material’s quality, verifying color and pattern accuracy, ensuring the correct sizing, and examining the stitching quality.

The process also includes testing the fabric’s strength and durability, confirming the proper labeling and packaging, and ensuring that the products comply with both the importing and exporting countries’ regulatory standards.

As an example, we will present you below in the article a real inspection report of a service we conducted for a temple.

Sampling plan and AQL for Outdoor Textile Pre-Shipment Inspections

We verify mass production quality based on your Acceptable Quality Limits (AQL), identifying and classifying defects to offer an overview of your product’s quality.

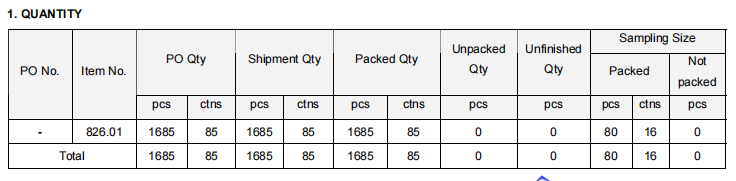

In our outdoor camping tent pre-shipment inspection example, the total number of pieces produced is 1685 tents. The first step is to determine the number of tents to inspect, which is where the sampling size comes into play. The sampling size isn’t just a random selection of units; it’s a carefully calculated number based on specific criteria, ensuring a representative and efficient inspection process.

- Workmanship Check: This involves assessing the overall quality and workmanship of the tents. For a batch size of 1685 pcs, a General Level II (GII) approach is recommended. In practical terms, this means inspecting 80 pcs.

- On site Check: Sometimes, certain aspects of the product require more focused attention. The on site check involves:

- Assembly check: 5 Samples

- Transportation Drop Test: 1 Samples

- Zipper function check: 80 Samples

- Rub and tape test on Logo: 5 Samples

- Product measurement: 5 Samples

- Barcode readability check: 5 Samples

To learn more about AQL, read our article dedicated article: How to Use AQL for Quality Control Inspection?

Comprehensive Outdoor Textile Inspection Checklist

At GIS Inspection, our outdoor textile pre-shipment inspection checklist covers the following criteria:

- Quantity Verification

- Product Workmanship Verification

- Product Style and Construction Inspection

- Functional and Performance Tests

- Measurement Data Check

- Package and Packaging Inspection

- Product Labelling and Markings Inspection

In the section below, we present the details of each criterion, including pictures, based on our example of outdoor tent inspection.

1. Quantity Verification

The first step in any pre-shipment inspection is the verification of the quantity. This evaluation checks if the actual quantity ready to be shipped to the client matches the quantity indicated in the purchase order (PO). The key aspects that need to be assessed during this stage include:

- The precise count of products manufactured, confirming they match the quantity specified in the PO.

- Verification of style or model numbers, ensuring every product aligns with the designated style.

- Verification of the color, ensuring they meet the precise specifications provided in the P.O.

For our tent inspection example, we have reported the quantity as per the following in our inspection report.

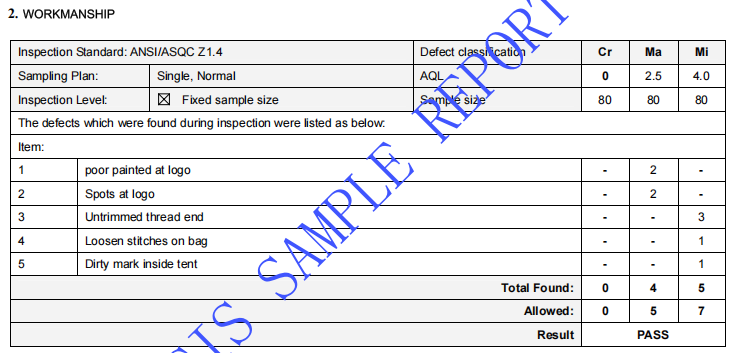

2. Product Workmanship Verification

Visually inspecting the product’s physical conditions, appearance, and cleanliness.

Those visual defects are categorized by defect category in a table within the inspection report as follows:

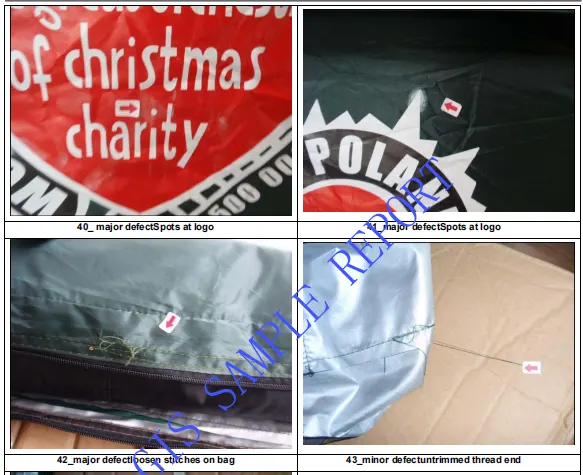

Here are examples of quality defects that we identified during the outdoor camping tent inspection:

3. Product Style and Construction Inspection

Our inspectors verify if the style and color of the outdoor textile product match the approval sample and the client’s technical file.

- Verifying if the product matches the same style and materials as the approval sample.

- Inspecting if the same materials as the sample have been used which prevents discrepancies in quality, feel, and overall appearance.

- Checking if the actual products match the client’s technical file. It ensures that the final product adheres to the specific design, quality, and material requirements set by the client.

4. Functional and Performance Tests

- Assembly check

- Transportation Drop Test

- Zipper function check

- Rub and tape test on Logo

- Product measurement

- Barcode readability check

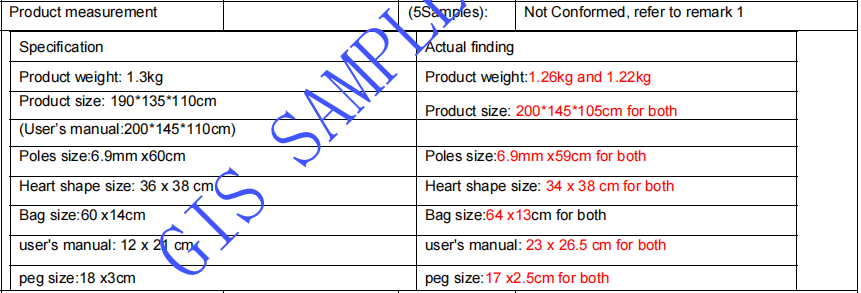

5. Measurement Data Inspection

During the inspection, precise measurements are a critical aspect to evaluate. This involves verifying several key dimensions to ensure consistency and adherence to design specifications (within tolerances or out of tolerances).

For this tent inspection, product weight, Product size, Poles size, Heart shape size, Bag size, user's manual, peg size are measured to guarantee they align with the design specifications.

In the tent pre-shipment inspection report, the results of the measurement data check are presented in a table as follows:

6. Package and Packaging Inspection

This stage is essential not only for upholding the brand’s image but also for ensuring that the packaging is robust and suitable for transit, minimizing the risk of damage. It includes:

- Packing method and conditions check to ensures the method of packing is appropriate for the product, protecting it from damage during transit and storage. It includes the carton dimensions, carton weight, sealing method (staples, adhesive, plastic band or metal band), and the carton quality.

- Shipping marks/labels check to verify the accuracy and visibility of shipping marks and labels aids in proper handling and routing during shipping.

- Retail package artwork check to ensures the packaging aligns with brand standards and marketing requirements, enhancing customer appeal.

7. Product Labelling and Markings Inspection

Label and marking test to verifying that the label & marking have the correct content.

GIS Inspection expertise in outdoor textile inspection

With offices across China and Southeast Asia, GIS Inspection performs Pre-Production Check, During Production Check and Final Random Inspection to assess outdoor textiles including shell jackets, ski jackets, hiking backpacks, tent, sleeping bag, outdoor rugs, camping folding chair, picnic blankets, awning fabric and more in all of China, Vietnam, Bangladesh, India, Pakistan, Philippines, etc.

At GIS Inspection, we help you ensure product quality, avoid supply chain disruptions and protect your brand reputation.

Contact our outdoor textile quality assurance experts to customize your inspection requirements.

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.