GIS inspector is conducting a quality inspection on home appliance products exported to Europe for our UK client.

Quality inspection is a systematic process of examining and evaluating products to ensure they meet the specified standards and requirements before they reach the consumer.

It involves checking the products against a golden sample or predefined criteria such as design specification, materials, dimension, functionality, packaging and more. The results of the inspection are then compiled into a report, that indicates whether or not the product conforms to the specifications.

Product inspection can be conducted at various stages of the manufacturing processes. Understanding each quality control type helps manufacturers and buyers maintain consistent quality, reduce defect rates, and prevent costly shipment issues.

This article explains the 4 main types of third-party quality Inspection:

- Pre-Production Inspection (PPI)

- During Production Inspection (DPI)

- Pre-Shipment Inspection (PSI)

- Container Loading Supervision (CLS)

1. Pre-Production Inspection (PPI)

gis inspecctor is conducting pre-production inspection in a factory in China

What Is Pre-Production Inspection (PPI)?

Pre-Production Inspection (PPI), also known as an initial production check, is performed at the beginning of the production process or even before the start of manufacturing to assess the quantity and quality of the raw materials and components, and whether they are in conformity with product specifications.

Pre-production inspection is one of the best ways to ensure that your product meets your requirements. It keeps your suppliers in check, your orders shipping on time and, ultimately, ensures customer satisfaction. Pre-Production Inspection also can reduce or eliminate communication issues regarding production timelines, shipping dates, quality expectations and others, between you and your supplier.

What are the benefits of Pre-Production Inspection (PPI)?

- Act an early warning signal to identify and rectify defects before mass production.

- Take control of the product quality from the raw materials, procedures.

- Any non-nonconformity is immediately reported to avoid delay in shipment.

- Can measure your manufacturer’s ability to meet your requirements and quality objectives.

- Diminish the risk of your supply chain getting interrupted.

What does the Pre-Production Inspection (PPI) Check?

At GIS Inspection, we conducting the PPI as the following checklists:

- Check the raw materials and components used in production;

- Sample and test semi-finished products to detect potential defects;

- Evaluate the quality system of the production line;

- Assess the management and ability of production equipment;

- Assess the production capacity of the manufacturer;

- Provide technical advice to the factory to improve product quality and minimize defects;

- Assess production schedule.

When to Conduct Pre-Production Inspection (PPI)?

An Initial production inspection’s main goal is to highlight quality risks before that of manufacturing mass production.

Buyers should consider an Initial Production Check for conduct production inspection when:

- Work with a new manufacturer or supplier, a PPI ensures they actually have the materials you paid for and assures the factory meet your requirements.;

- Book a large amount of cargo, any issues that needed to be addressed before mass production;

- The entire manufacturing process are lasting several months.

It is the first step in ensuring that your supplier will consistently manufacture good quality products, which is used to identify quality issues early on in production and to prevent them from causing bigger issues further down the track.

2. During Production Inspection (DPI)

What is During Production Inspection (DPI) ?

A During Production Inspection (DPI) is conducted while the product is being manufactured, usually when 30-50% of the production is complete. This inspection evaluates the quality of the products being produced in the middle stage of the production process.

During Production Inspection is crucial as it allows for real-time monitoring of the manufacturing process. Inspectors check for consistency and conformity to specifications, ensuring that any issues can be addressed immediately. By identifying defects early in the process, businesses can save time and resources and reduce waste, ultimately leading to a more efficient production cycle.

What are the benefits of During Production Inspection (DPI)?

During production check improves production processes and quality and ensure the product meets specification prior to release and shipment.

- Act an early warning signal to identify and rectify defects

- Managing your production schedule more effectively avoids delays in shipment.

- Avoiding monetary losses due to reworking and returned orders.

- Improving the quality of your products before mass produced.

- Increasing customer satisfaction that will be based on high-quality, on-time deliverables.

What does the During Production Inspection (DPI) Check?

- Sample and evaluate the products for safety, performance, design, function and appearance;

- Check for any defects and deviation from clients’ specifications and/or given samples;

- Evaluate the packing methods and packing material;

- Check and evaluate the quality management of production line;

- Evaluate the production progress against the schedule and predict if the shipment is on schedule;

- Give practical and effective advices to improve quality in accordance of the findings.

When should You Conduct a During Production Inspection (DPI)?

During Production Inspections (DPI) are usually scheduled at a specific point in the production process when a certain percentage of the products have been produced. This is usually done to identify and address any issues that may arise during the production process before the product is completed.

- The products have strict compliance requirements e.g. electrical and electronic products. To ensure that product quality and specifications are in line with standards and regulations during the mass production stage.

- The existing factory performs poorly constantly.

- The production quantity is large and on-time shipment is important avoiding production delays.

3. Pre-Shipment Inspection (PSI)

a GIS inspector is conducting pre shipment inspection in a factory in China

What Is Pre-shipment Inspection (PSI)?

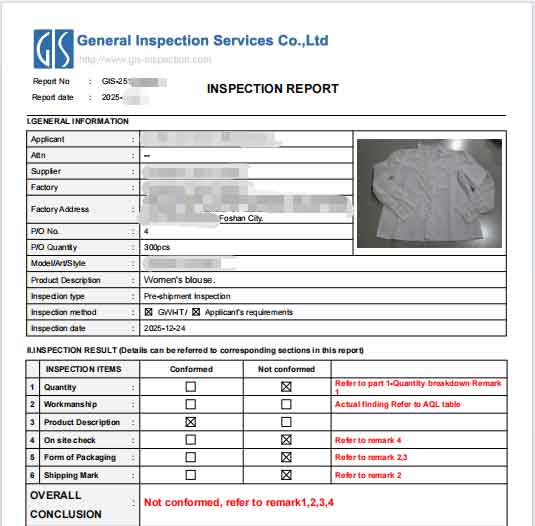

A pre-shipment inspection (also known as Final Random Inspection) is performed when production is 100% completed and 80% of the products are packed for shipment. It aims to visual check on all the relevant aspects of the product: quantity, components, assembly, aesthetics, function, size, labeling, packaging, and other required parameters.

This type of inspection is vital for confirming that products are packaged correctly, function as intended, and meet all safety and regulatory standards. It serves as a final checkpoint to ensure that only high-quality products reach the customer.

PSI is suitable for nearly all types of consumer goods purchased in Asia. The final inspection report is typically used by the importer to authorize shipment and trigger payment.

Finding your reliable third-party quality inspection agency here: Top 28 Third-party Quality Inspection Service Agencies and Companies in China

GIS conduct AQL sampling inspection based on ANSI/ASQC Z1.4 (ISO 2859-1) criteria and produce detailed inspection reports based on a defined AQL.

Learn: How to Use AQL for Quality Control Inspection?

What are the benefits of Benefits of Pre-shipment Inspection (PSI)?

With your suppliers an ocean away, how can you ensure that the goods you receive meet your expectations for quality? The final random inspection is one of the most common third-party quality China inspection services conducted by importers working with manufacturers to verify the quality of your products before they are shipped.

The benefits of Pre-shipment inspections include:

- Identify any defects or deviations from the approved sample before goods leave the factory.

- Ensure the correct quantity of products is produced and ready for shipment.

- Confirm that product labels, barcodes, and shipping marks are accurate and comply with customer or regulatory requirements.

- Encourage suppliers to adhere to quality standards by conducting regular pre-shipment inspections.

What does the Pre-shipment Inspection (PSI) Check?

At GIS Inspection, we perform a comprehensive check on randomly selected samples to verify product safety and compliance. our Psi inspection process covers every critical detail:

- Check quantity, accessories, assortment, labeling, shipping mark, etc. against the purchase order, given samples and technical documents;

- Sample and evaluate product for safety, design, function, appearance, and performance;

- Check for any defects and deviation against the technical standards or requirements;

- Assess packaging form.

Who Need a Final Random Inspection (FRI)?

Not every buyer has the same requirements, but for the following types of clients, an FRI is an indispensable part of their risk management strategy:

1. International Importers and Retailers

If you are buying goods from overseas, especially in Asia and cannot visit the factory yourself, you need a trusted third-party inspection agency like GIS Inspection. It acts as your "eyes and ears" to ensure the products match your approved golden sample and industries regulations.

2. First-Time Buyers Working with New Suppliers

When starting a partnership with a new manufacturer, the risk of "quality fade" or misunderstanding specifications is high. An PSI inspection provides the necessary verification to build long-term trust.

3. Brands with High Quality Standards

For businesses in industries like electronics, medical devices, or high-end consumer goods, even a 1% defect rate can lead to brand damage. These clients require strict AQL (Acceptable Quality Level) sampling to ensure compliance.

4. E-commerce & Amazon FBA Sellers

Platforms like Amazon have strict requirements for packaging, labeling, and product functionality. One bad batch can lead to account suspension or a flood of negative reviews. FRI ensures the goods are "FBA-ready."

5. Buyers Dealing with Large Volume Orders

When the financial stakes are high, you cannot afford to ship 10,000 units of defective products. The cost of an inspection is a fraction of the cost of a total loss or a global recall.

Read: What is a Pre-shipment Inspection?Procedure, Checklist, and Cost

Why Choose GIS Inspection for Your Final Check?

With 20 years of experience, GIS Inspection understands that the final stage is your last chance to prevent a mistake from leaving the factory floor.

- Only full-time inspectors but part-time or freelancers are used, less bribery risks;

- Service rate is $150/Man-day all-inclusive in China’s major manufacturing regions;

- A strong network of 200+ full-time inspectors located in China, Vietnam, India, Malaysia and more Asia countries;

- 14+offices for management locally based in Guangzhou and all major manufacturing regions;

- Inspection reports delivered within 24 hours after the inspection;

- Dedicated account manager and customer service 24/7.

Quality Inspection Examples: Strategic Quality Partnership with a Leading Russian Uniform Brand

Client Profile: A Russian client with its own established uniform brand was sourcing large volumes of uniforms from manufacturers in China. Due to the brand’s high positioning and strict quality standards, the client required consistent product quality across all shipments and production batches.

The client came to GIS Inspection with a clear mission. They didn't just need a checklist ticked off; they demanded a localized third-party inspection team capable of executing a rigorous quality control protocol, including:

- Strict adherence to a custom-made inspection checklist.

- Precise dimensional measurement and fit evaluation.

- Detailed defect classification for specialized uniform fabrics.

- A need for "beyond reporting"—they required Corrective Action Plans (CAP) to guide factories through necessary reworks.

The GIS Solution: A Tailored Quality Roadmap

Leveraging our 20 years of industry experience, GIS Inspection moved beyond the standard "Pass/Fail" model to provide a comprehensive strategic service:

1. Technical Alignment & Inspector Training

Before the first inspection, we conducted deep-dive sessions with the client to understand their "brand DNA." We held specialized training for our local inspectors, ensuring they mastered the client’s specific measurement points and seam strength requirements.

2. Rigorous On-Site Execution

During the Final Random Inspection (FRI) and During Production Inspection (DPI), our team meticulously followed the client’s checklist. Every deviation—from a loose thread to a 2mm measurement variance—was documented with high-resolution evidence.

3. Professional Rework & Rectification Support

When defects were found, GIS didn't just halt the shipment. We issued Professional Rectification Plans. We sat down with the factory’s production managers to explain the root causes and provided a roadmap for reworking the uniforms to meet the brand's standards.

The Result: A Lasting Strategic Alliance

The initial trial was a success. By providing transparent communication and actionable data, GIS helped the client reduce their return rate and significantly improved the factory’s output quality over time.

What started as a single inspection project has evolved into a Long-term Strategic Cooperation. Today, GIS Inspection is the exclusive quality partner for this brand in China, ensuring that every uniform delivered to Russia is a perfect representation of the brand’s promise.

4. Container Loading Supervision (CLS)

What is Container Loading Supervision (CLS)?

A Container Loading Supervision is conducted during the container loading process of products. This inspection ensures that the correct products and correct quality are loaded and that the products are properly loaded in containers with optimal conditions.

What are the Benefits of Container Loading Supervision (CLS)?

Confirm that the correct quantity of goods is loaded as per the purchase order or shipping instructions.

Verify that packaging is adequate to protect goods during transit, especially for fragile or sensitive items.

Ensure the container is properly sealed to protect goods from moisture, pests, or contamination.

Monitor the entire loading process to ensure goods are securely packed and sealed.

Confirm that the container is properly locked and sealed with the correct seal number recorded.

What does the Container Loading Supervision (CLS) Check?

At GIS Inspection, our Container Loading Supervision (CLS) is the final crucial step in our quality control chain. Our expert inspectors:

- Check the container condition;

- Verify the products loaded;

- Closely monitor the loading process;

- Verify the quantity;

- Ensure proper handling of the goods and proper stack in the container.

As soon as the inspection is finished, the container will be sealed with the shipping line seal. And seal number is recorded in the loading report.

Frequently Asked Questions of Quality Inspection

Q1: What are the 4 main types of quality inspection?

The 4 main types of quality inspections are Pre-Production Inspection (PPI), During Production Inspection (DPI), Pre-Shipment Inspection (PSI), and Container Loading Inspection (CLI).

Q2: Do I need all four types of inspections?

Not necessarily. While a full-cycle quality plan offers the highest level of security, most businesses choose their inspections based on supplier reliability, product complexity, order value and volume, and risk tolerance.

If you are unsure where to start, 80% of our clients begin with the PSI inspection. Some electronics product customers include DPI to gain more control over the timeline.

Q3: Which inspection is best for new suppliers?

For new suppliers, consider this 2-step GIS quality control plan:

Factory Audit: Before the order (to ensure they have the capacity and ethical standards).

Pre-shipment Inspection (PSI): To provide the final "Pass" for shipping and payment.

Inspect by GIS Inspection

General Inspection Service-GIS is an international third-party quality control inspection company headquartered in China in 2005, which provides a professional range of product quality inspection and factory audit services to clients across multiple industries. We have set up an inspection network covering China, Vietnam, India and Malaysia. By employing only full-time inspectors, GIS is trusted by more than 12,000 brands globally.